Ⅰ. Introduction to 15kV RMU Test Tooling

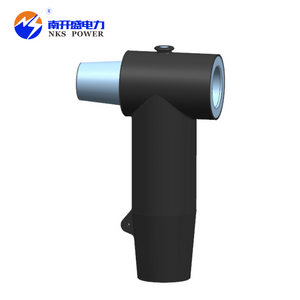

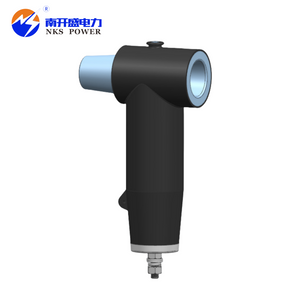

The C-type bushing RMU test tooling can be directly coupled to the C-type outer cone bushing of the equipment without the need to manufacture additional test cables, and provides lead wires for factory testing of the high-voltage side of the ring main unit or on-site acceptance of power distribution equipment. It has good insulation performance, extremely low partial discharge, easy installation and disassembly, and high efficiency.

The product matches the C-type bushing in EN50180-50181

Implementation standards: IEC60502.4, GB/T12706.4

Ⅱ. Features of 15kV RMU Test Tooling

1. Superior Electrical Performance

Constructed from high-quality silicone rubber material, it delivers outstanding electrical properties, ensuring stable operation in high-voltage environments.

2. Integrated Preformed Design

Employing integrated preforming technology, the product features a compact overall structure with extremely low partial discharge levels. This effectively reduces power loss and enhances system safety.

3. Reusability and Convenient Operation

Designed for practicality and durability, it can be reused multiple times, significantly lowering usage costs. Installation and removal are simple and quick, requiring no complex tools or specialized skills, saving time and labor costs.

4. Compliance with International Standards

Manufactured in strict adherence to international and national standards such as IEC 60502-4 and GB/T 12706-4, ensuring reliable product quality and performance to meet stringent global market requirements.

Ⅲ. Electrical Performance Parameters of 15kV RMU Test Tooling

NKS-15CS-02 |

Items |

Parameter |

Technical Parameters | System Voltage |

15kV |

Rated current |

630A |

Frequency withstand voltage(AC) |

42kV/5min |

Partial Discharge |

15kV<5pC |

Impulse voltage |

95kV |

Ⅳ. Application of 15kV RMU Test Tooling

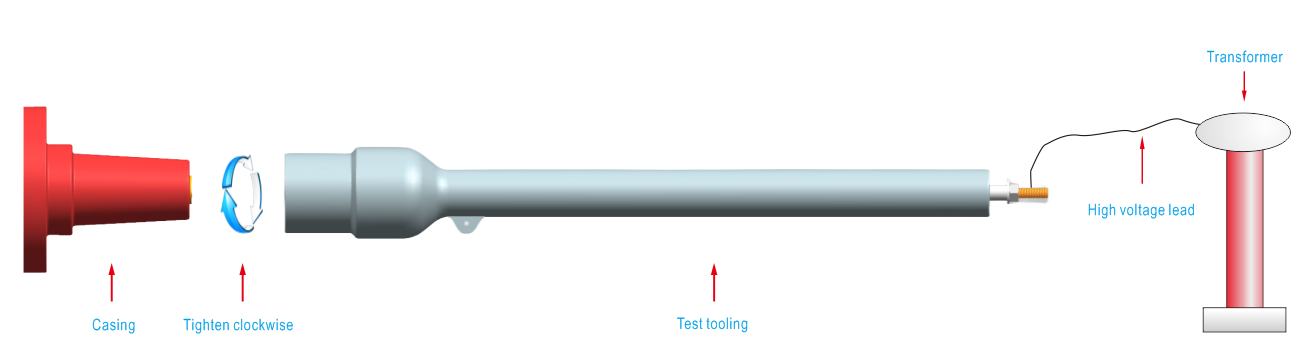

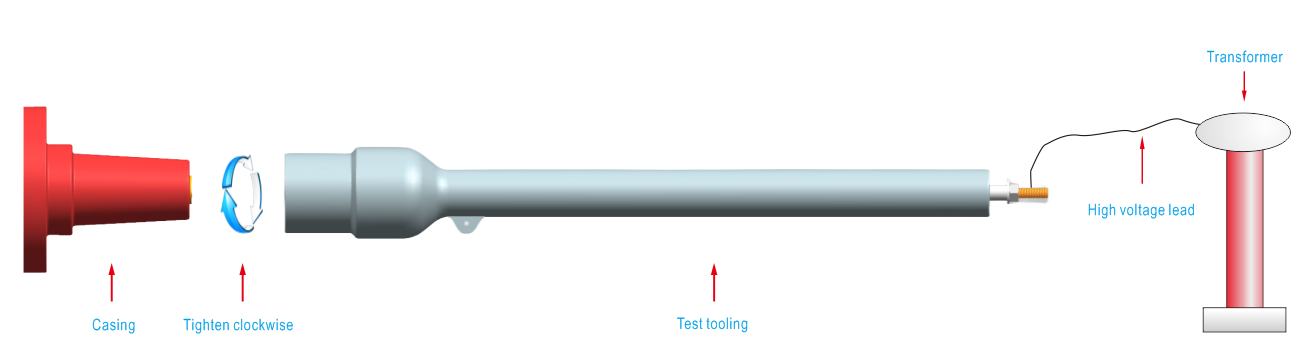

1. Wipe the inside of the test tooling and the outside of the epoxy casing with cable cleaning paper. After the detergent has completely evaporated, apply silicone grease evenly.

2. Screw the test tooling into the epoxy sleeve and rotate it clockwise at 30N/m until it is tightened in place. Just turn it counterclockwise when disassembling.

3. Connect the end conductor of the test tooling to the high-voltage lead.

4. Conduct the test after the grounding wires of each part are reliably grounded.