NKS High-Quality Cable Connectors for Electronic Development

In today's industrial and electronic worlds, cable connectors are extremely important. Those electric cable connectors by NKS belong to the best quality range—highly reliable. Not only do these connectors provide a stable electrical connection, but the configurations of the connectors also allow for options that suit different requirements in various applications.

Ⅰ. Classification of Electric Cable Connectors

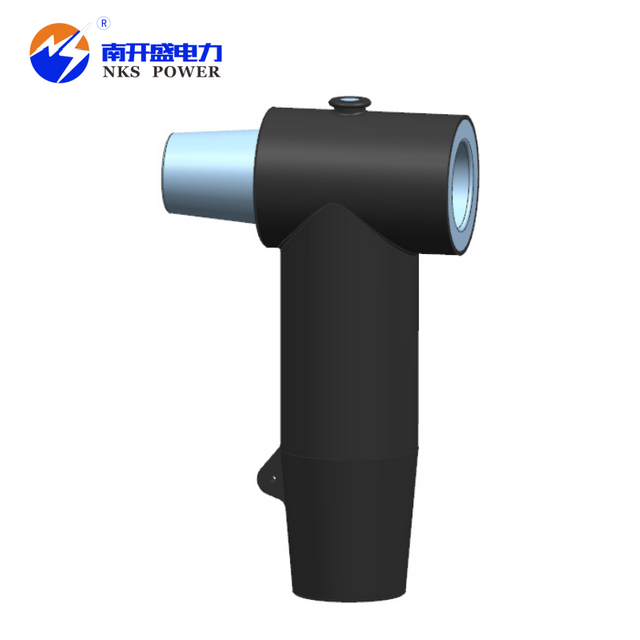

Separable Connector: A key component extensively utilised in power systems, enabling the safe disconnection and reconnection of electrical power during transmission. Designed for high reliability and safety, this connector facilitates rapid and secure power isolation when maintenance or equipment replacement is required.

Busbar Connector: This device is made for busbar system connections. It keeps power flowing smoothly even with lots of current. It’s built to spread the current evenly and keep the system working well. It's a must-have for big power systems.

Ⅱ. Characteristics of Electric Cable Connectors

Use quality materials and accurate production to ensure steady work in many conditions. Match. Make the item with a plan that keeps it working well with old systems to lower upgrade and change costs, and a simple setup. Easy design helps quick fitting, cutting down setup time and mistakes. Toughness stands long use and bad weather, making tools last longer, safe meets world safety rules for safe running.

Ⅲ. Selection Guide

1. Define Application Requirements

Current Capacity: Select an appropriate current capacity based on the device's power requirements. For equipment requiring high current transmission, such as industrial machinery or electric vehicles, choose power connectors with high current capacity.

Voltage Rating: Select an appropriate voltage rating according to the device's voltage requirements. Different devices may require varying voltages, from low-voltage portable equipment to high-voltage industrial machinery; choosing the correct voltage rating is crucial.

2. Consider Environmental Factors

Temperature: In high-temperature environments, connectors must exhibit excellent heat resistance. For instance, in automotive engine compartments or industrial furnaces, high-temperature-resistant connectors are essential.

Humidity: In damp or submerged conditions, connectors require waterproof or moisture-resistant properties. Waterproof connectors are indispensable in diving equipment or outdoor electronics.

Vibration: In environments with significant vibration, such as aerospace equipment or heavy machinery, connectors must possess robust vibration resistance to ensure stable connections.

3. Consider Physical Characteristics

Dimensions and Shape: Choose the right size and shape for your connectors. If you have a small device, get a mini connector. For big machines, go for larger ones.

Mounting Method: Choose suitable mounting methods according to the equipment's installation requirements. Common methods include soldered, plug-in, and screw-type. For instance, equipment requiring frequent insertion/removal should utilise plug-in connectors.

Ⅳ. Selecting Cable Connector Supplier

1. Quality Standards

Connectors should be selected based on whether they comply with international standards, such as those of IEC or EIA. These standards have explicit rules regarding design, manufacture, and testing, ensuring good function and reliability between the connectors themselves and with other equipment.

2. Supplier Reputation

Choose Cable Connector Supplier who have a track record and quality assurance to back them up. Products bought from reputable Cable Connector Suppliers are of higher quality most of the time, plus better after-sales support.

3. Certification and Testing

Make sure to check if the connectors being considered have been certified and tested under any relevant certifications, such as UL certification or CE marking. These will show that the connector has gone through intensive tests on matters of safety and performance.