NKS Cable Joints: High-Reliability Solutions

Cable joints, as vital components in cable connections, are crucial for ensuring the stability and safety of power transmission. As a specialist cable joint manufacturer, NKS offers diverse joint solutions to meet varied customer requirements. Our products are renowned within the industry for their exceptional performance and reliability.

Ⅰ. Classification of Cable

1. Cold Shrink Joints

Cold shrink joints utilise cold-shrink materials that automatically contract after installation, forming a tight seal around the cable to provide superior waterproofing and insulation.

2. Heat Shrink Joints

Heat shrink joints require heating to achieve a secure connection between the cable and joint. These joints offer excellent heat resistance and chemical resistance, making them suitable for diverse environmental conditions.

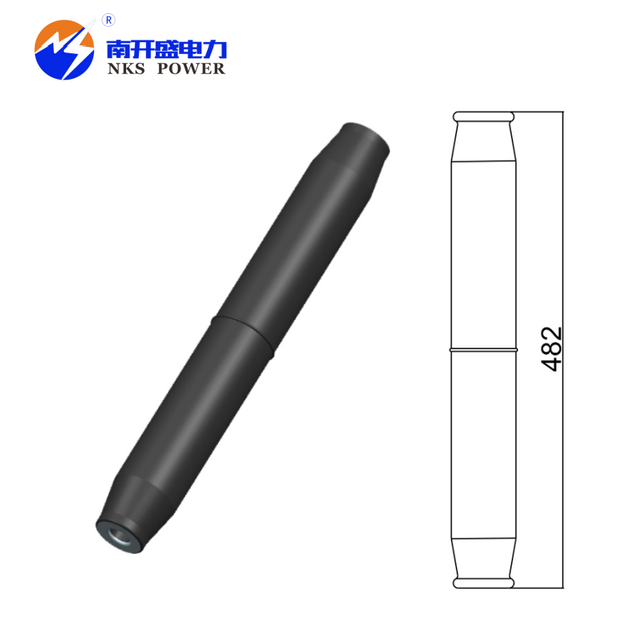

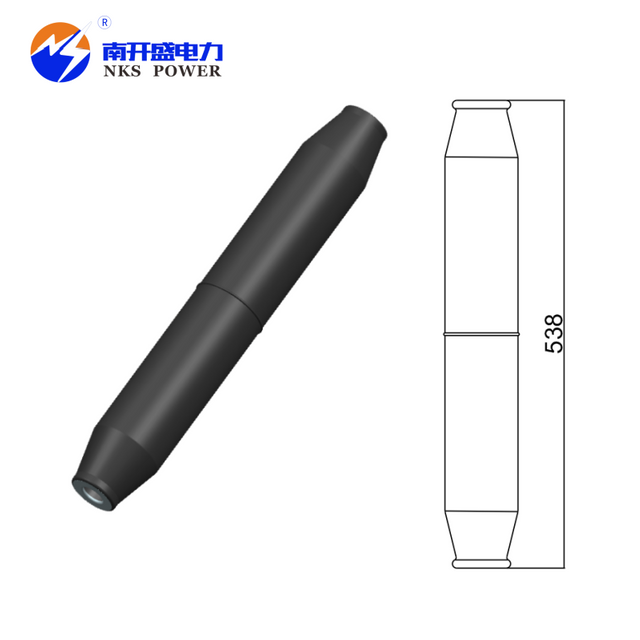

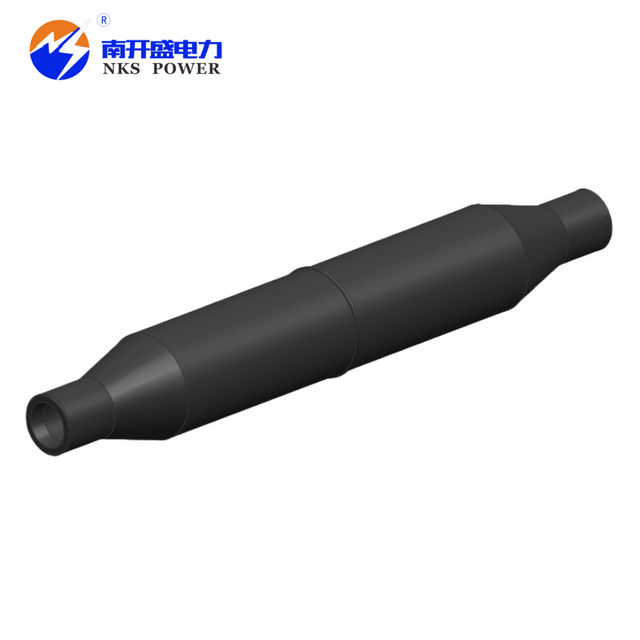

3. Premoulded Joints

Premoulded joints are pre-formed and can be directly installed onto cables. They offer straightforward installation, making them suitable for rapid construction and maintenance.

4. High Voltage Joints

High voltage joints are specifically designed for high-voltage environments, capable of withstanding high voltage and current surges to ensure stable power transmission.

Ⅱ. Performance of the cable joint

1. High insulation performance

It maintains great insulation efficiency in wet basements, tough outside weather, or industrial places with electromagnetic noise. It stops leakage and short circuit accidents well, making sure electrical systems work safely.

2. Superior waterproofing

This system uses high-level sealing tech to block moisture from getting inside. This keeps cables safe from both wetness and rust. Even if cables stay underwater for a long time or in very damp spots, it helps them stay in good shape and last longer. This matters for setups like power sending and communication lines that have to.

3. Heat and chemical resistance

It does great work in hot places and fights off damage from many types of acids. If it is used in any harsh state, be it acid or base, and so on, it keeps up its full strength and makes sure the cable joints work well for a long time.

4. Simple installation

Whether cold-shrink, heat-shrink, or pre-moulded joints, all feature straightforward installation procedures.

5. Exceptional durability

Manufactured from high-quality materials to guarantee long-term joint resilience.

Ⅲ. Applications

1. Communications Networks

As information technology keeps growing fast, more communication base stations and data centers are being built. Cable joints are used to connect communication cables. They make sure signals can travel quickly and steadily, and they reduce signal loss and interference.

2. Industrial Automation Systems

A cable joint manufacturer focuses on quality products and solutions. Basic connecting by the cable joints does not compromise performance or reliability. They are known for being trustworthy in power transmission, communication networks, and industrial automation.

3. Building Electrical Installations

Internal cabling shall comply with high standards of safety and performance. NKS joints assure good electrical continuity, and since the building space is limited, its compact design will easily fit in. It ensures that there will be no short circuit and overheating at the junctions of the cables, hence safe operation of the electrical system within a building.

Ⅲ. Selection Guide

Cable Type: Choose appropriate joints based on the cable type used (e.g., copper, fibre optic).

Environmental Conditions: Consider the installation environment's temperature, humidity, and chemical corrosion exposure to select joints with corresponding protective properties.

Voltage Rating: Choose high-voltage or low-voltage joints according to the cable's voltage rating.

Installation Ease: Opt for joints with straightforward installation based on your construction conditions and time constraints.

Cost-Effectiveness: Match the joint performance with the price so that those products offering the best value for money can be selected.

As a cable joint manufacturer, NKS has taken it upon itself to provide only high-quality products and solutions. Our cable joints satisfy the basic need for connection, outperforming in terms of performance and reliability. It is an application where power transmission, communication network, and industrial automation depend on its trustworthiness.