Premoulded Termination: Delivering Efficient Connection Solutions for Power Systems

NKS POWER is a premoulded termination manufacturer that puts premoulded terminations as one of its connection solutions into the critical connections for power systems. Premoulded terminations are engineered to provide very secure, stable electrical connections and long-term protection between cables and conductive components of substation and distribution equipment. This category involves the supply of low-voltage to medium-high voltage levels and different installation environments with premoulded termination products. We take our cue from customer field application requirements to combine material science knowledge with molding process expertise in delivering terminations having excellent insulation performance, environmental resistance, and long-term stability. As a manufacturer, we deliver every premoulded termination that meets our standard through rigorous factory testing, quality control, and customized services that ensure reliable connections and quick field installation in actual operation.

Ⅰ. Introduction to Premoulded Termination

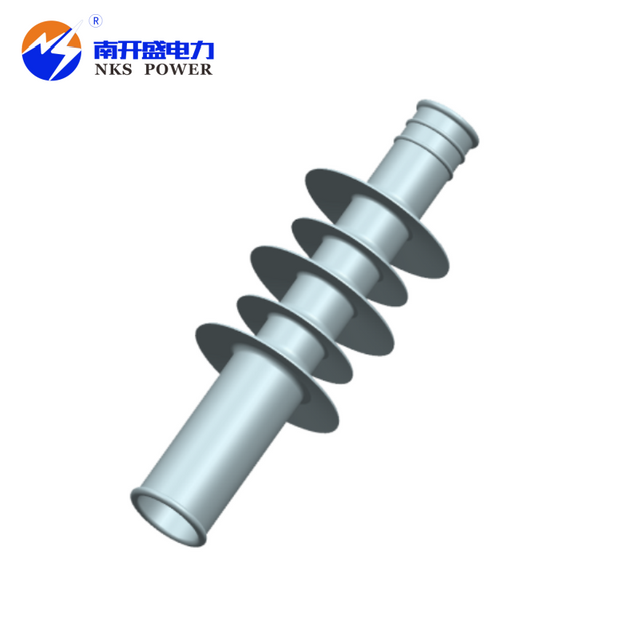

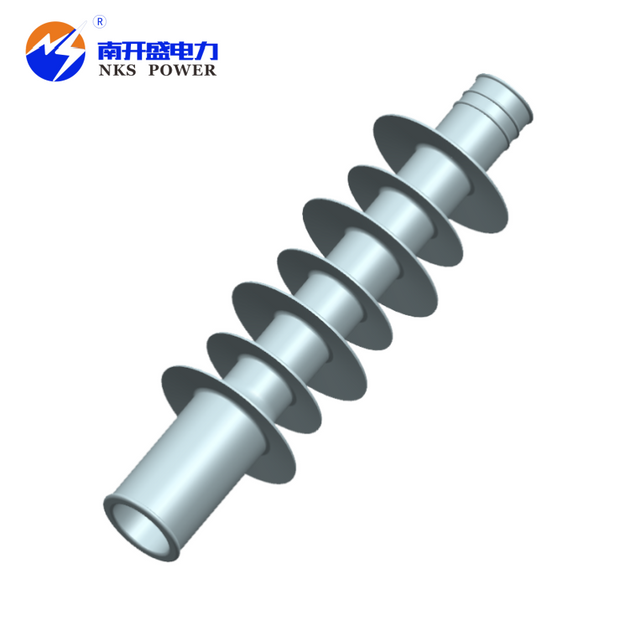

Pre-molded cable termination are inlaid with stress control parts in the insulation body in advance in the factory production, no interface exists, through the stress control parts to effectively solve the problem of stress concentration at the cable shield cut. Using silicon rubber high resilience, high temperature resistance and strong aging resistance, and cable insulation to adopt interference combined design. This ensures that the interface between cable insulation and accessories is closely combined without internal creepage. In order to meet the four types of pollution environment, and design the external insulation of the accessories. 36kV prefabricated cold shrinkage power cable accessories are suitable for the connection of 21/36kV, 26/36kV single/three core XLPE power cable.

Product execution standards: IEC60502.4, GB/T12706.4

III. Advantages of Premoulded Termination

1. Integrated Manufacturing & Consistent Performance Stability

As a premoulded termination manufacturer, we exercise full process control over material selection, mold design, and molding techniques. This ensures sustained mechanical strength, insulation integrity, and protection ratings throughout long-term operation.

2. Quick Set-Up & Easy Fixes

Pre-made shape cuts down on the need for much work at the site making setup easy, saving worker hours, and cutting down on mistakes during setup while raising work speed in the field.

3. Top Insulation and Environmental Strength

Choice of material and design focus on high-level insulation, moisture barriers, UV blocking as well as weather proofing support long-time use outdoors or in tough conditions.

4. Stringent Quality Control and Traceability

As the manufacturer, we provide end-to-end quality control from material procurement and production line processes to factory testing, ensuring every batch passes performance and safety inspections with full traceability.

5. Customization and Technical Support

We offer tailored solutions based on site conditions, cable specifications, and wiring configurations. Technical consultation, installation training, and after-sales service further assist clients in achieving optimal integrated solutions.

6. Industry-Compliant Comprehensive Solutions

Adhering to universal industry standards throughout design and manufacturing, we leverage proprietary process expertise to deliver stable, reliable preformed terminal products and solutions.

Ⅳ. Features of Premoulded Termination

It is made from high-performance liquid silicone rubber

High mechanical strength, suitable for a variety of power cables

Strong UV resistance and strong weather resistance

Has excellent insulation properties, corona resistance and tracking resistance

Simple design and reasonable structure

Built-in stress control, uniform electric field distribution

Suitable for copper and aluminum cables

Suitable for crimp lugs and mechanical lugs

Quick assembly and simple installation