Ⅰ. Introduction to15kV RMU Test Tooling

The test tooling can provide lead wires for the high-voltage side of RMU factory testing or on-site acceptance of distribution equipment. It has good insulation performance, extremely low partial discharge, easy installation and disassembly, and high efficiency.

Ⅱ. Features of 15kV RMU Test Tooling

NKS Power's 15kV RMU testing tools feature multiple outstanding capabilities and advantages, making them an ideal choice for electrical testing.

1. Superior Insulation Performance

Utilizing high-quality silicone rubber material ensures stable operation in high-voltage environments, effectively preventing electric shocks and short circuits.

2. Extremely Low Partial Discharge

The integrated pre-molded design minimizes partial discharge, reducing energy loss and enhancing system safety.

3. Convenient Installation and Removal

Designed for practicality and ease of use, the installation and removal process is simple and quick, requiring no complex tools or specialized skills, saving time and labor costs.

4. Reusability

High-quality materials and advanced manufacturing processes guarantee product durability, enabling multiple reuses and reducing long-term operating costs.

5. Compliance with International Standards

Manufactured in strict adherence to international and national standards such as IEC 60502.4 and GB/T 12706.4, ensuring reliable product quality and performance that meets stringent global market requirements.

6. Efficient Testing Solution

Provides an efficient and reliable testing solution for factory testing and on-site acceptance, enabling users to complete testing tasks quickly and accurately while improving work efficiency.

Ⅲ. Electrical Performance Parameters of 15kV RMU Test Tooling

NKS-15CS-01 | Items | Parameter |

| Technical Parameters | System Voltage | 15kV |

Rated current | 630A |

Frequency withstand voltage(AC) | 42kV/5min |

Partial Discharge | 15kV<5pC |

Impulse voltage | 95kV |

Ⅳ. Application of 15kV RMU Test Tooling

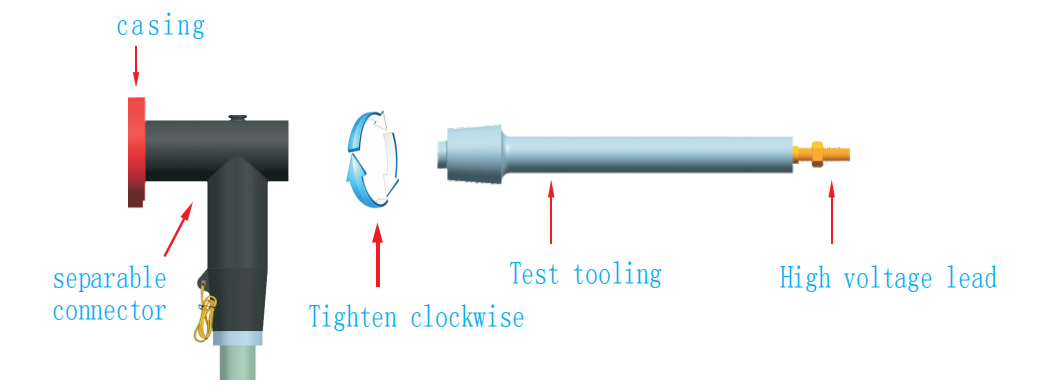

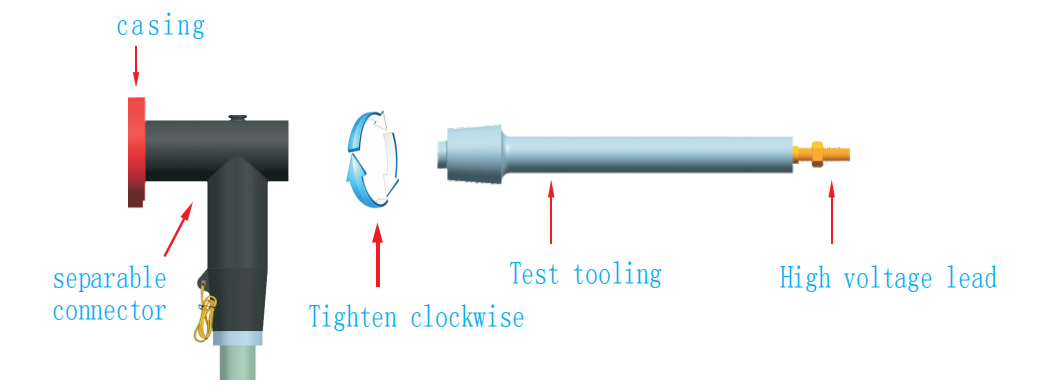

1. Use clean paper to clean the test tooling and casing. Wait until the cleaning agent has completely evaporated, and then apply silicone grease evenly.

2. Screw the test tooling into the tail of the connector body and rotate it clockwise to 30N/m until it is tightened in place. When disassembling, just rotate it counterclockwise.

3. Lock the high-voltage lead with the end conductor of the test tool.

4. Conduct the test after the grounding wires of each part are reliably grounded.