I. Introduction

In the world of medium and high-voltage electrical power systems where safety, reliability, and sustainability depend on safe cable terminations, heat shrink termination is one of two major technologies used for ensuring protection and insulation—cold shrink technology being the other. Choice between these two ways by engineers, contractors, or project managers is a determinant factor in installation time, long-term performance, and total project cost. The article will examine what really sets apart cold shrink from heat shrink cable terminations by taking a look at their mechanisms, advantages, and ideal applications to offer a cogent guide as to which should be used on an electrical project.

II. Understanding Heat Shrink Termination

1. Core Principle and Installation Process

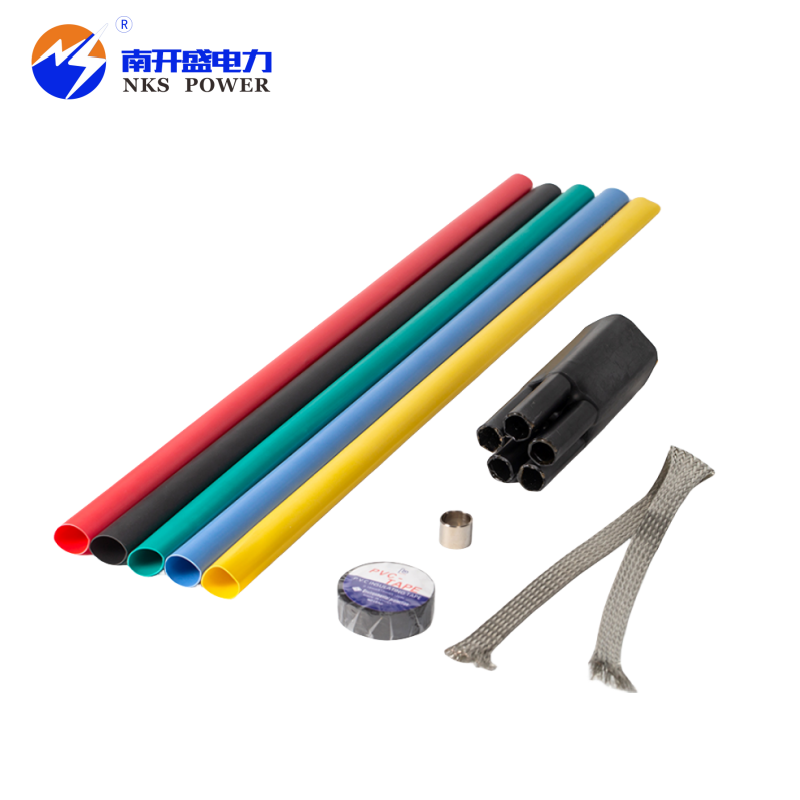

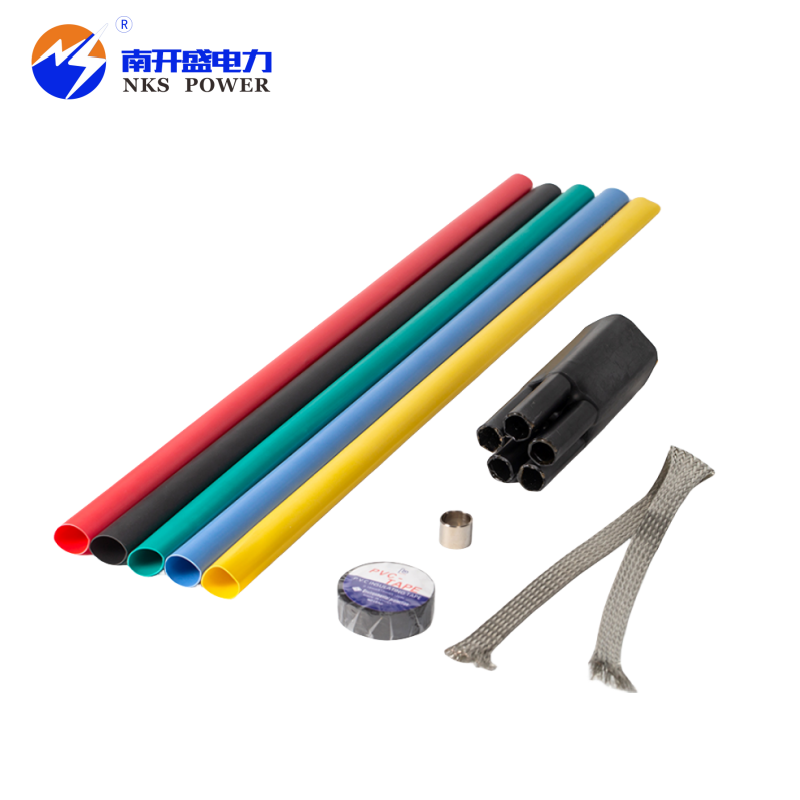

The basic principle in a heat shrink termination lies in the application of heat to initiate its sealing and insulating features. Termination kits are mostly made up of Polyolefin or any advanced material, which after going through a cross-linking process is expanded to a larger size during production.

(1) Heat Activation and Memory

With the application of even heat by a propane or butane torch, or gun specially developed for this purpose, molecular recovery takes place. The material remembers what its original shape was to shrink back tightly and uniformly onto the cable substrate. Careful application of heat is also required to avoid voids or air pockets that may be introduced and destroy the integrity of the seal.

(2) Activation of Internal Adhesive

This process produces a higher seal Internal adhesive, which is typically made from thermoplastic material inside the sleeve is activated by the same heating process. The thermoplastic then melts and runs into all small surface textures on the cable and sets up a solid single-piece plastic plus chemical plus water plus corrosion seal against environmental water and other contaminants.

2. Key Advantages of Heat Shrink

This technology offers several significant benefits that have made it a trusted solution for decades.

(1) Environmental Resilience and Durability

Environmental resilience and durability in the extreme because heat shrink is made of materials engineered for high dielectric strength, and great resistance to UV, ozone, and extremes of temperature. It may be used as a description, but it is truly appropriate for long-term durability in harsh outdoor or industrial conditions where keeping the elements out is not always possible.

(2) Versatility Across a Wide Spectrum of Applications

These systems are available for a vast range of voltage ratings, demonstrating their versatility. This range includes specialized products like a robust 36kV Heat Shrink Indoor Termination for higher voltage applications, a standard 24kV Heat Shrink Indoor Termination for common industrial uses, and even a 1kV Heat Shrink Termination for lower voltage scenarios.

III. Understanding Cold Shrink Termination

1. Main Principle and Installation Process

Cold shrink technology uses a pre-expanded core mechanism which keeps the elastomeric termination component expanded until ready for use.

(1) Core removal Mechanism for Installation

The principal way for removal permits installation with no tools. The installer places the unit over the prepared end of the cable, which terminates held in an expanded condition by a rigid removable plastic core or woven plastic pull cord. Installation is completed by firmly pulling this core right out from the middle of the sleeve.

(2) Elastic memory

When the core is pulled out, the engineered rubber sleeve (usually made from EPDM or silicone) at once shrinks back onto the cable because of its natural elastic recovery force. It offers a very strong consistent grip that does not require any heat and does not need any tools or flames to apply, hence sealing immediately.

2. Key Advantages of Cold Shrink

The most pronounced advantage of cold shrink terminations revolves around installation efficiency and safety.

(1) Unmatched Installation Speed and Capability

The process is remarkably fast and simple, often completed in minutes. This speed is a significant advantage for large-scale projects or tight deadlines. Furthermore, since no heat is involved, installations can proceed safely in rain, high humidity, or windy conditions, where a 15kV Heat Shrink Indoor Termination would be impractical or unsafe to install.

(2) Enhanced Safety and Flexibility

Removing an open flame makes cold shrink the safer method, not arguably but factually in hazardous, confined, or potentially explosive atmospheres. The material is elastic offers great flexibility as well as resistance to electrical tracking hence it is resilient in conditions where there is possible movement of cable or vibration.

IV. Key Differences Summarized

1. Installation Method and Tools

The most obvious difference is the installation process and the required tools.

(1) Heat source and Skilled Technique

The technician must be skilled enough to apply the source of heat evenly so as to attain a bubble-free complete shrink. More time is required and indeed more expertise so as not to under-shrink or burn the material.

(2) Cold Shrink is a Tool-free and Skill-minimized Process

Cold shrink needs no outside tools, power source, or special heating method. Its setup is quick and less reliant on worker ability, lowering the chance for mistakes and giving a steady outcome each time.

2. Environmental and Site Considerations

Environmental factors play a crucial role in selecting the appropriate technology for the job site.

(1) Specific Environmental Limitations

Heat shrink is limited by specific environmental factors. Generally, it is not recommended to install heat shrink in wet or windy conditions because moisture can easily be trapped under the sleeve and wind cools the torch flame making application uneven. This makes it best suited for use in controlled or dry environments.

(2) Superior Installation Flexibility

Cold shrink can be installed in practically any environment thus offering greater flexibility regarding emergency repairs or projects that cannot wait for favorable weather conditions. The ability to work in all weather proves a great logistical advantage on numerous job sites.

V. Choosing the Right Termination for Your Project

The choice of a cold or heat shrink is not about which is better, but about which is more appropriate for the project's context, environment, and constraints. Factors to be considered by engineers include the environment of installation, skill level that can be marshaled, time available for installation, and finally long-term performance requirements.

Wherever projects demand time, safety, and installation under any weather condition, cold shrink is preferably used. Where applications have demands for rugged hardened environmental sealing, maximum UV resistance, and whenever an appropriate heat source can be safely and effectively applied, then heat shrink remains to be the best-proven solution. Technical consultation and careful consideration of the specific cable type, environmental exposure, voltage level, and installation constraints are always recommended.

VI. Conclusion

Cold shrink and heat shrink termination technologies are strong and stable ways of sealing and insulating cable terminations. It is through systems that are technologically advanced that the choice boils down to specific project requirements. The heat shrink forms a highly durable bond sealed with adhesive under a process activated by heat, while cold shrink achieves unmatched installation speed, safety, and ease with its novel pre-expanded core design. With an understanding of their different working principle advantages and best scenarios to use them in, experts can decide which one to use for the infrastructure security that would serve them well into the future.