Introduction

Look down any quiet suburban street, and you'll see the familiar markers of our modern electrical grid. There are the overhead lines, the wooden poles, and, sitting discreetly on a concrete pad, a green metal box—a pad-mounted transformer. It’s easy to overlook this common piece of street furniture, but it serves as a gateway to a hidden world. Beneath our feet lies a complex network of underground cables, an invisible infrastructure that powers our homes, businesses, and daily lives. In this subterranean grid, where reliability and safety are paramount, components must perform flawlessly under immense pressure. One of the most crucial, yet rarely discussed, of these components is the elbow connector.

This isn't a piece of hardware you'll find in a typical toolbox. It is a highly engineered device that forms the critical link between the miles of buried power cables and the equipment that distributes electricity to our communities. The integrity of this single connection point can mean the difference between an uninterrupted power supply and a neighborhood-wide outage. This article aims to pull back the curtain on the power system elbow connector, demystifying its essential function, exploring its different types, and highlighting its absolutely vital role in the delivery of safe, reliable electricity in the 21st century.

Defining the High-Voltage Elbow Connector

First, it’s essential to draw a clear line between the component in question and the fittings found in a local hardware store. When one hears "elbow connector," the mind often jumps to plumbing or simple electrical conduit—a basic piece of PVC or metal designed to help pipes or wires make a turn. A high-voltage elbow connector operates in an entirely different league. It is a specialized, robustly insulated component engineered specifically to terminate medium- and high-voltage underground cables and connect them safely to apparatus like pad-mounted transformers, switchgear, and other electrical junctions. Its characteristic 90-degree shape is purpose-built, designed to perfectly interface with a standardized part on the equipment known as a bushing.

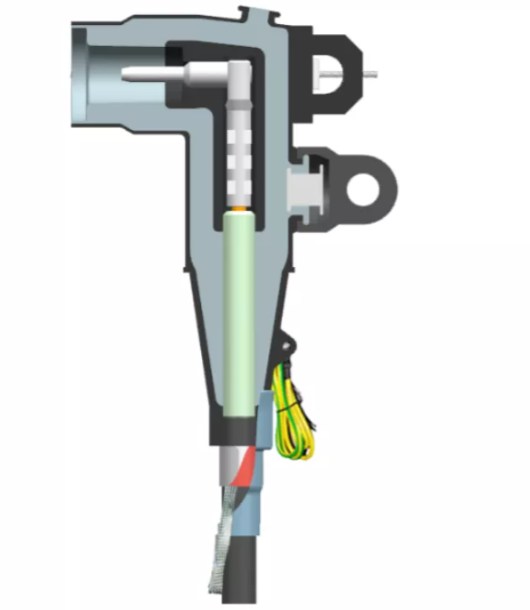

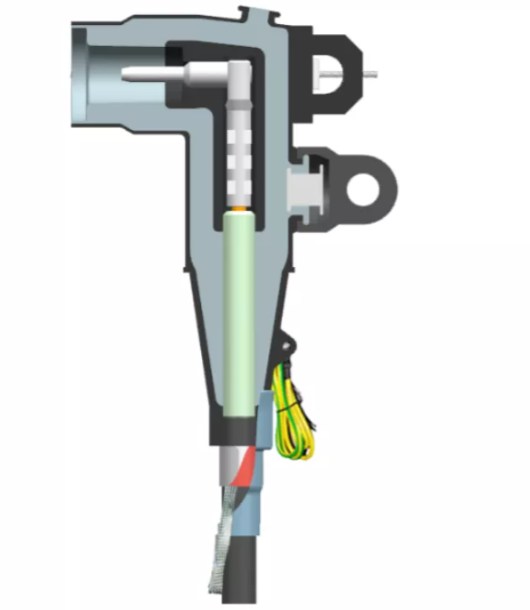

The importance of this connection goes far beyond simply changing direction. We're talking about electrical systems that typically operate between 5,000 and 35,000 volts (5kV to 35kV). At these levels, a secure, perfectly shielded, and insulated connection isn't just a good idea—it's a fundamental requirement for safety and system stability. The elbow connector achieves this through a sophisticated multi-layer construction. It consists of an inner conductive layer, a thick primary layer of EPDM rubber insulation, and an outer semi-conductive layer. This design creates what is known in the industry as a "deadfront" component. When installed correctly, the entire outer surface of the connector is at ground potential, meaning it is safe to the touch, a massive leap forward in safety for utility workers and the public. This self-contained, shielded system protects the high-voltage connection from moisture, dirt, and other environmental contaminants that could otherwise lead to catastrophic failure.

The Two Main Families: Loadbreak vs. Deadbreak Connectors

While all elbow connectors serve the same basic purpose of making a safe, shielded connection, they are not all created equal. Their most significant distinction lies in how they can be operated. The entire product family is split into two main categories, and the difference is fundamental to how utility companies manage the power grid: can the connection be broken while electricity is flowing? This single operational question separates them into loadbreak and deadbreak connectors.

Loadbreak Elbow Connector: Flexibility for a Live Grid

The term "loadbreak" refers to the connector's ability to be connected or, more critically, disconnected while the circuit is "under load"—that is, while it is energized and actively carrying electrical current. This capability is a game-changer for grid operators. Imagine a scenario where a fault needs to be isolated or a transformer requires maintenance. With a loadbreak system, a utility worker can use a special insulated tool called a "hot stick" to safely pull the elbow off the transformer bushing, interrupting the flow of power at that specific point without de-energizing the entire feeder line.

How is this possible without creating a massive, dangerous electrical arc? Loadbreak elbow connector contains an internal mechanism designed specifically for this purpose. As the elbow is pulled away from the bushing, a special probe inside the connector extinguishes the electrical arc that naturally forms when a live circuit is broken. This remarkable feature provides immense operational flexibility. It allows utilities to re-route power, perform sectionalizing (isolating sections of the grid), and carry out repairs far more efficiently, often minimizing the number of customers affected by an outage. They are the go-to choice for connection points where future switching operations are anticipated.

Deadbreak Elbow Connector: The Secure, Permanent Connection

In contrast, "deadbreak" elbows are designed with a different philosophy in mind: security and permanence over operational flexibility. As their name implies, these connectors can only be operated when the circuit has been confirmed to be de-energized. Attempting to disconnect a deadbreak elbow on a live circuit would be extremely dangerous, drawing a significant electrical arc that could cause equipment damage and severe injury.

Deadbreak connectors are used for more static, long-term installations where routine switching is not a requirement. Think of the main connection to a large transformer or a critical junction in the underground system. These connections are intended to be made once and left undisturbed for years. To that end, their design often features a more robust and secure interface, frequently involving a bolted connection that ensures a tight, reliable fit and excellent current-carrying capability. While they lack the on-the-fly flexibility of their loadbreak counterparts, they provide an exceptionally stable and secure connection point for the backbone of the underground grid.

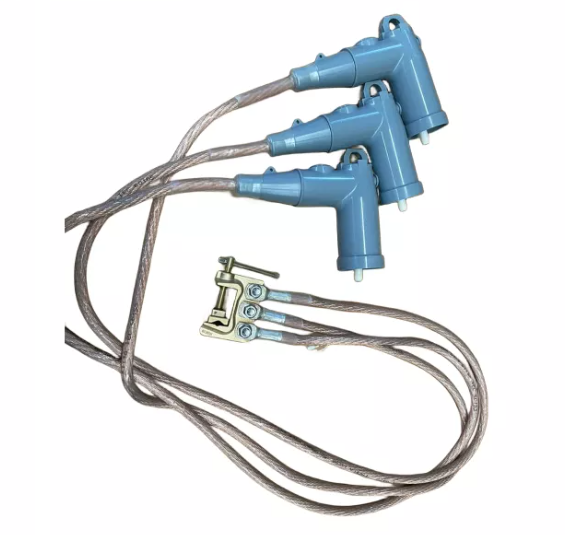

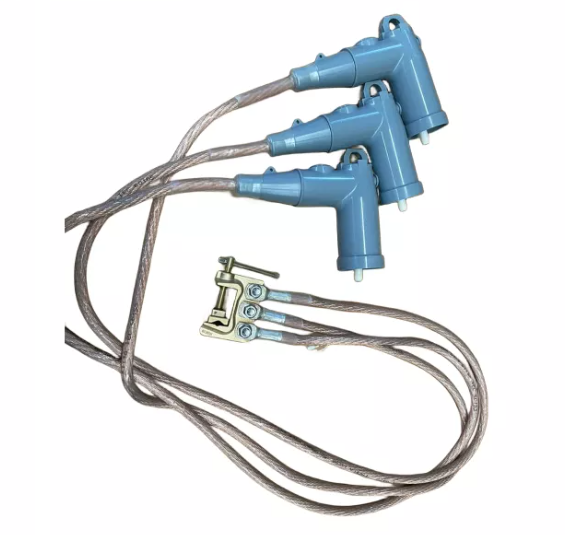

Similarly, Ground Elbow Connectors fall under the deadbreak category, as they are also designed for de-energized circuits and ensure a secure connection to the ground system. These connectors play a crucial role in providing a reliable and safe path for fault currents to flow into the earth, protecting both the equipment and personnel. Like other deadbreak connectors, they are typically used in long-term installations where safety and permanence are paramount.

At a Glance: Comparing Loadbreak and Deadbreak Elbow Connectors

To make the distinction perfectly clear, here is a direct comparison of their key attributes:

Feature | Loadbreak Connector | Deadbreak Connector |

Operation | Can be operated on an energized circuit | Must be operated on a de-energized circuit |

Primary Use | Switching, sectionalizing, temporary feeds | Permanent transformer and switchgear connections |

Key Design Feature | Internal arc-quenching mechanism | Secure, often bolted, interface |

Operational Flexibility | High | Low |

Why Elbow Connectors are Essential to Modern Power Distribution

The development and widespread adoption of the deadfront elbow connector has been one of an underground revolution, fundamentally changing the design, safety, and reliability of modern power distribution networks. Their importance can be seen in several key areas.

First and foremost, they enhance grid reliability. Underground systems are, by their nature, protected from wind, ice, and falling tree limbs—common culprits of outages in overhead systems. The elbow connector extends this reliability down to the connection point itself. Its fully sealed and insulated design protects the critical interface from moisture, wildlife, and chemical contamination, preventing the flashovers and short circuits that can plague exposed connections.

Second, they represent a monumental improvement in public and worker safety. The deadfront design, where the outer surface is safely at ground potential, is a core safety feature. It allows utility personnel to work in the compact spaces of transformer cabinets with a significantly reduced risk of accidental contact with live high-voltage parts. This stands in stark contrast to older, "livefront" designs with exposed terminals.

Third, elbow connectors are a key enabler of underground infrastructure. In many new residential and commercial developments, placing power lines underground is now standard practice for aesthetic reasons and for building resilience against severe weather. Elbow connectors make this possible by providing a compact, safe, and reliable method for terminating cables and connecting them to pad-mounted equipment. Without this technology, the widespread adoption of underground distribution would be far more complex and hazardous.

Finally, they streamline maintenance and repairs. This is particularly true of loadbreak systems. The ability to quickly and safely sectionalize a circuit allows utility crews to isolate a problem, such as a faulted cable segment, and restore power to the majority of customers on the line while repairs are made. This surgical approach to grid management reduces outage durations and improves customer satisfaction, making the elbow connector a critical tool for the modern electrical utility.

A Look Inside: Components and Installation

An elbow connector is more than just a molded piece of rubber; it's a precision-engineered assembly of components that work in concert to manage high electrical stresses. Understanding its construction sheds light on why its proper installation is so critical.

Key Components of an Elbow Connector Assembly

While designs vary slightly between manufacturers, nearly all elbow connectors consist of a few core parts:

The Elbow Body: This is the main L-shaped housing, made of high-quality EPDM rubber. It provides the primary insulation and the external semi-conductive shield that makes the connector a deadfront device.

The Compression Lug: A specially designed aluminum or copper connector that is crimped onto the end of the power cable's conductor. It creates the physical and electrical connection point inside the elbow body.

The Loadbreak Probe: Found only in loadbreak elbows, this is the crucial component for extinguishing an electrical arc during live operation. It's an intricate piece of engineering that makes switching under load possible.

The Pulling Eye: A reinforced ring or hook molded into the front of the elbow. This is the attachment point where a lineman connects a hot stick for safe installation, removal, and switching.

A Matter of Precision: The Installation Process

It cannot be overstated: installing a high-voltage elbow connector is a job exclusively for trained and certified professionals. The long-term reliability of the connection is entirely dependent on meticulous, precise workmanship. A single mistake during installation can lead to a failure years down the road. The process involves several exacting steps: the cable's various layers (jacket, metallic shield, insulation, and semi-conductive screen) must be stripped back to precise, manufacturer-specified dimensions. All surfaces must be perfectly clean and free of contaminants. The lug is then crimped on with a specialized hydraulic tool, and finally, after applying a specific silicone lubricant, the elbow body is carefully slid into place. The goal is to create a perfectly sealed, void-free interface. Any air pocket or contamination can create a point of high electrical stress, eventually leading to insulation breakdown and failure.

Conclusion

From the quiet suburban transformer to the bustling commercial center, the elbow connector works silently, performing a job of immense importance. It is far more than a simple fitting; it is a sophisticated piece of electrical apparatus that embodies decades of material science and engineering. By providing a safe, reliable, and flexible connection point, it forms the very backbone of our modern underground power distribution systems.

The critical distinction between loadbreak and deadbreak elbows gives grid operators the tools they need for both permanent, robust installations and dynamic, flexible network management. Their deadfront design has fundamentally improved safety for utility workers, while their sealed construction ensures a level of reliability that overhead systems often struggle to match. So, the next time you see that green metal box on the corner, you'll know that inside, an unsung hero of the electrical world—the elbow connector—is reliably doing its job, keeping the critical link between the grid and your home secure.