Ⅰ. Introduction to 15kV RMU Test Cable Tray

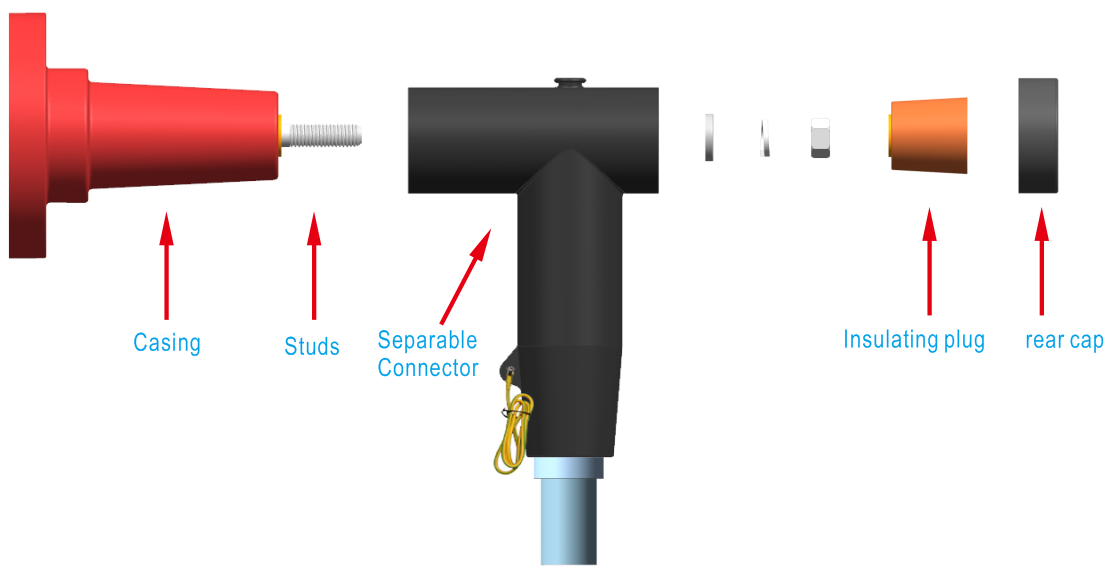

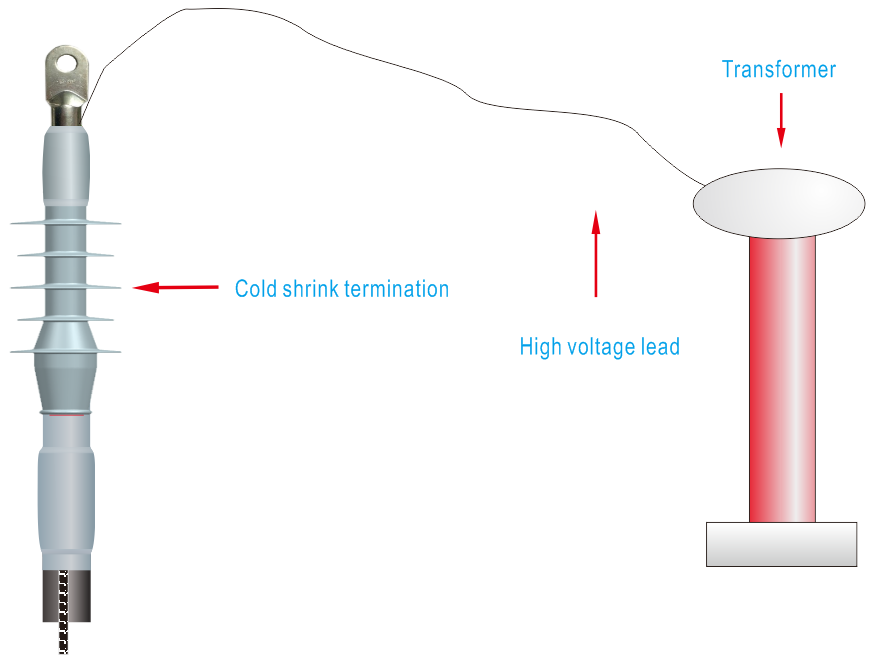

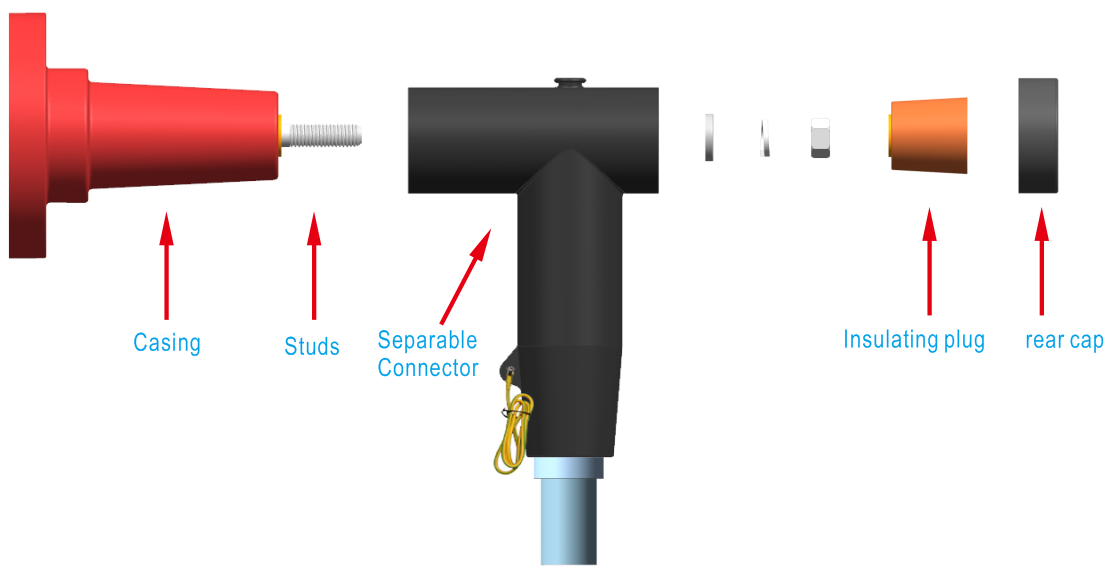

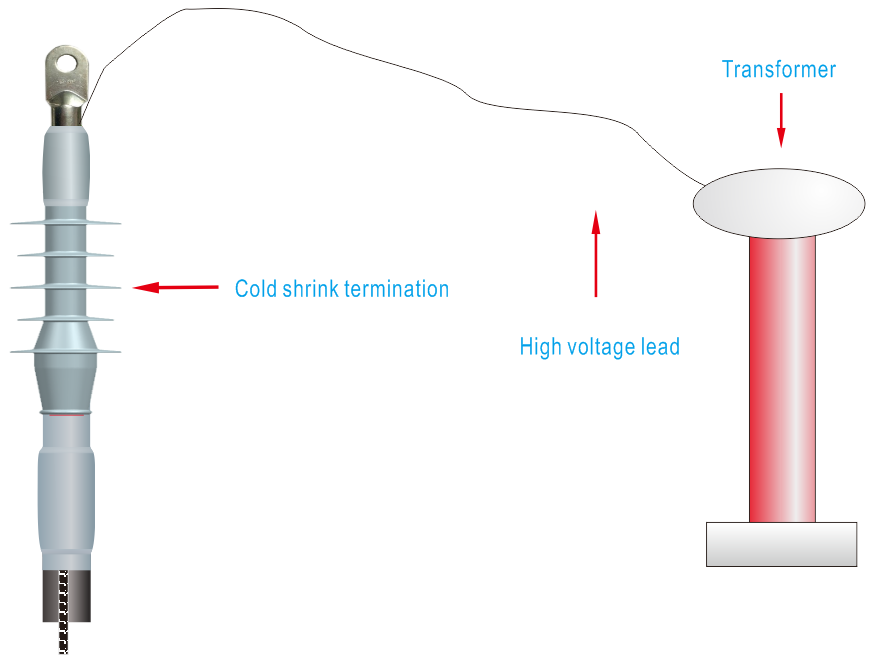

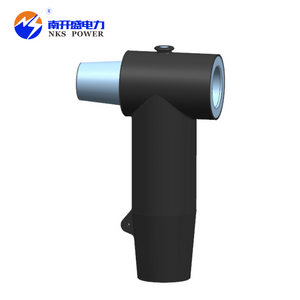

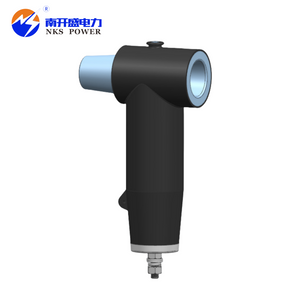

The 15kV test cable tray is composed of shielded elbow connectors, flexible rubber sheathed cables, and cold shrink terminations. It provides lead wires for the high-voltage side of the primary and secondary ring main unit grid-connected tests. It can provide full shielding and sealing from the line to the equipment, with good insulation performance, extremely low partial discharge, and easy installation and disassembly.

The product matches the C-type bushing in EN50180-50181

Implementation standards: IEC60502.4, GB/T12706.

Ⅱ. Features of 15kV RMU Test Cable Tray

Silicone material with excellent electrical properties

Flexible rubber cable, can be bent at will, the length can be customized

The pre-mold is formed in one piece and the partial discharge is extremely small.

Reusable, easy to install and disassemble

Ⅲ. Electrical Performance Parameters of 15kV RMU Test Cable Tray

NKS-15CS-03 | Items | Parameter |

Technical Parameters | System Voltage | 15kV |

Rated current | 630A |

Frequency withstand voltage(AC) | 42kV/5min |

Partial Discharge | 15kV<5pC |

Impulse voltage | 95kV |

Ⅳ. Application of 15kV RMU Test Cable Tray

1. Wipe the inside of the elbow connector of the test fixture and the outside of the epoxy sleeve with cable cleaning paper. After the detergent has completely evaporated, apply silicone grease evenly.

2. Insert the elbow connector into the epoxy resin sleeve and secure it with bolts. Tighten the rear insulation plug clockwise with a torque of 30N/m until it is tightened in place.

3. Connect the lug on the cold shrink termination side of the test fixture to the high voltage lead.

4. Conduct the test after the grounding wires of each part are reliably grounded.