Ⅰ. Introduction to 24kV RMU Test Tooling

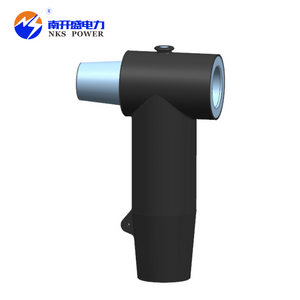

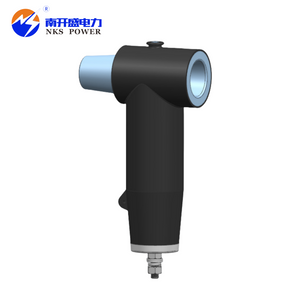

The 24kV Type C bushing test tooling consists of an inner cone test tooling and a cold shrink termination. The surface of the inner cone test tooling is sprayed with conductive silica gel to provide shielding and anti-interference. The cold shrinkage termination is used to increase the creepage distance and can be directly connected to the Type C of the equipment. The outer cone bushing coupling eliminates the need to make additional test cables and provides lead wires for the high voltage side of the ring main unit or for factory testing. On-site acceptance of power distribution equipment. It has good insulation performance, extremely low partial discharge, easy installation and disassembly, and high efficiency.

The product matches the C-type bushing in EN50180-50181

Implementation standards: IEC60502.4, GB/T12706.4

Ⅱ. Features of 24kV RMU Test Tooling

1. Superior Electrical Performance Silicone Rubber Material

The 24kV RMU Test Tooling utilizes high-quality silicone rubber material, selected for its outstanding electrical properties. It withstands high voltages without breakdown while providing stable electrical insulation, ensuring safe operation of power systems.

2. Integrated Preformed Design

The RMU Test Tooling employs an integrated preforming process, meaning all components are molded in a single operation during manufacturing. This ensures product integrity and consistency. This design significantly reduces the possibility of partial discharge, enhancing product reliability and durability.

3. Convenient Installation and Removal

The design prioritizes user experience, making installation and removal simple and efficient. Users can complete operations without specialized tools or complex procedures, significantly reducing installation time and lowering maintenance costs.

4. Reusability

The product's durability and reliability enable multiple reuses, enhancing economic efficiency while reducing resource waste—aligning with sustainable development principles.

Ⅲ. Electrical Performance Parameters of 24kV RMU Test Tooling for Type-C Casing

NKS-24CS-01 | Items | Parameter |

| Technical Parameters | System Voltage | 24kV |

Rated current | 630A |

Frequency withstand voltage(AC) | 54kV/5min |

Partial Discharge | 20kV<5pC |

Impulse voltage | 125kV |

Ⅳ. Application of 24kV RMU Test Tooling for type-C Casing

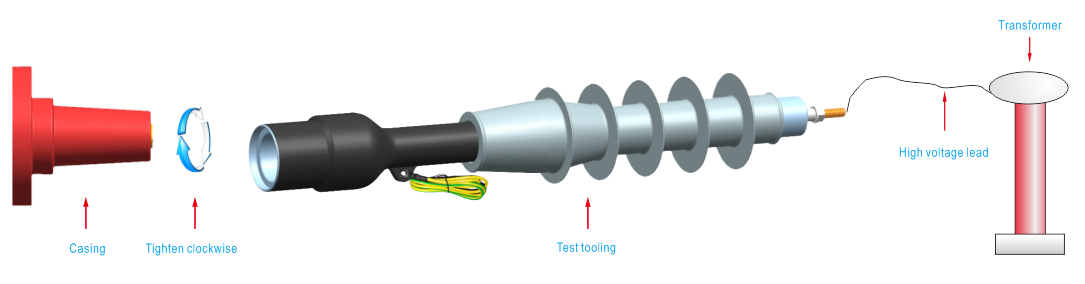

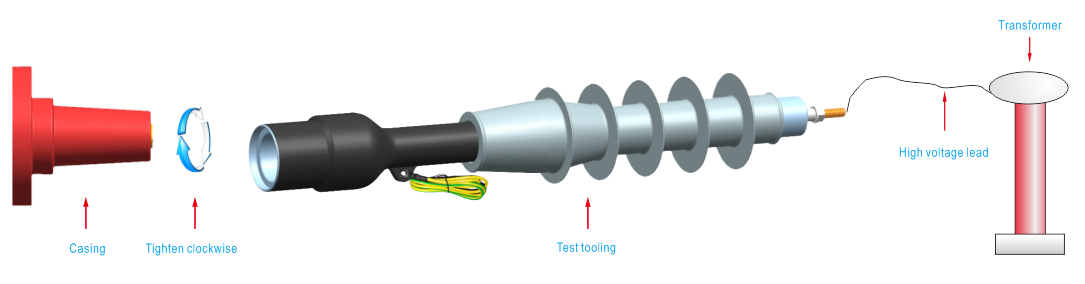

1. Wipe the inside of the test tooling and the outside of the epoxy casing with cable cleaning paper. After the detergent has completely evaporated, apply silicone grease evenly.

2. Screw the test tooling into the epoxy sleeve and rotate it clockwise at 30N/m until it is tightened in place. Just turn it counterclockwise when disassembling.

3. Connect the end conductor of the test tooling to the high-voltage lead.

4. Conduct the test after the grounding wires of each part are reliably grounded.