Ⅰ. Introduction to Low-Voltage Heat Shrink Tubing

Low-voltage heat shrink tubing are made of cross-linked environmentally friendly polyolefin heat shrinkable materials after irradiation expansion. They can provide high insulation strength and electrical resistance and are suitable for cable connections, cable terminations, busbar copper bars, and electrical equipment. Anti-corrosion and insulation protection.

Ⅱ. Features of Low-Voltage Heat Shrink Tubing

1. High Mechanical Strength

NKS Power's low-voltage heat-shrink tubing is renowned for its exceptional mechanical strength, making it highly suitable for various types of power cables. Whether during installation or long-term operation, these sleeves withstand external pressures and abrasion, safeguarding the internal cables from damage. This high-strength characteristic ensures cable integrity and extends service life, reducing maintenance and replacement costs associated with cable damage.

2. Strong UV Resistance and Weather Resistance

Our heat-shrink tubing exhibits outstanding UV resistance and weather resistance, meaning it maintains its physical and electrical properties even under extreme

climatic conditions such as intense sunlight, high temperatures, or humid environments. This characteristic is particularly crucial for outdoor applications, as it prevents aging, cracking, or performance degradation from prolonged exposure to harsh weather, ensuring the long-term stability and reliability of the cable system.

3. Excellent Insulation Properties

NKS Power's heat shrink tubing delivers superior insulation properties, including resistance to corona discharge and tracking. These characteristics are vital for preventing cable failures under high-voltage conditions. Superior insulation reduces power loss, enhances energy efficiency, and minimizes electric shock risks, thereby safeguarding the secure operation of power systems.

Ⅲ. Electrical Performance Parameters of Low-Voltage Heat Shrink Tubing

Test Items | Test Methods | Test Requirements |

Tensile Strength | ASTM D638 | ≥10Mpa |

Ultimate elongation | ASTM D638 | ≥300% |

Tensile Strength after Aging | ASTM D638 | ≥8Mpa |

Ultimate elongation after aging | ASTM D638 | ≥250% |

Longitudinal shrinkage | ASTM D2671 | ±5% |

Dielectric constant | ASTM D2671 | ≥18Ω.cm |

voltage breakdown strength | ASTM D149 | ≥25kv/mm |

Volume resistivity | ASTM D257 | >1014Ω.cm |

density | ASTM D792 | 1.22g/cm² |

Flame retardancy | UL 224 | VW-1 |

complete shrinkage temperature | ASTM D792 | 130±5℃ |

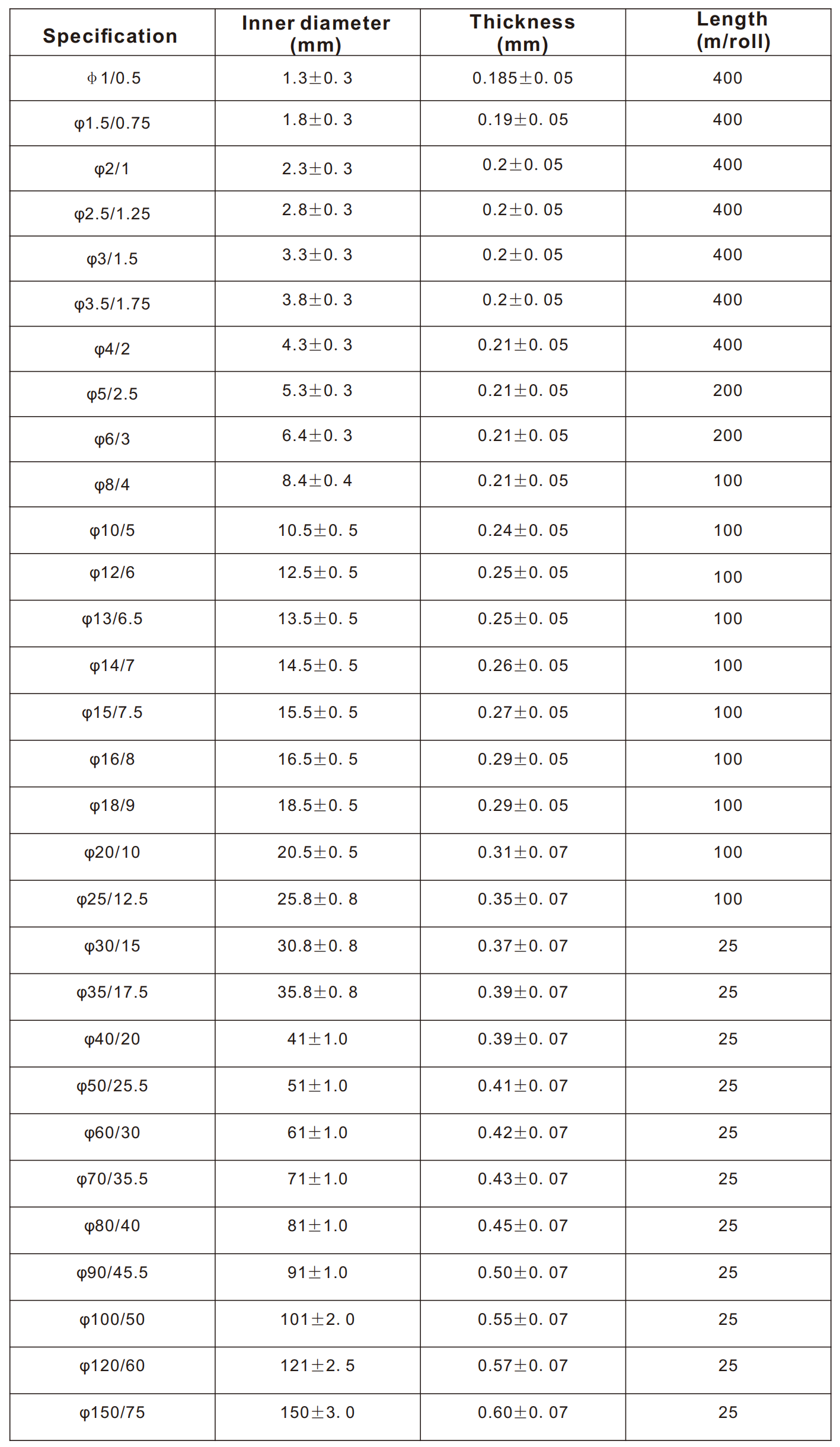

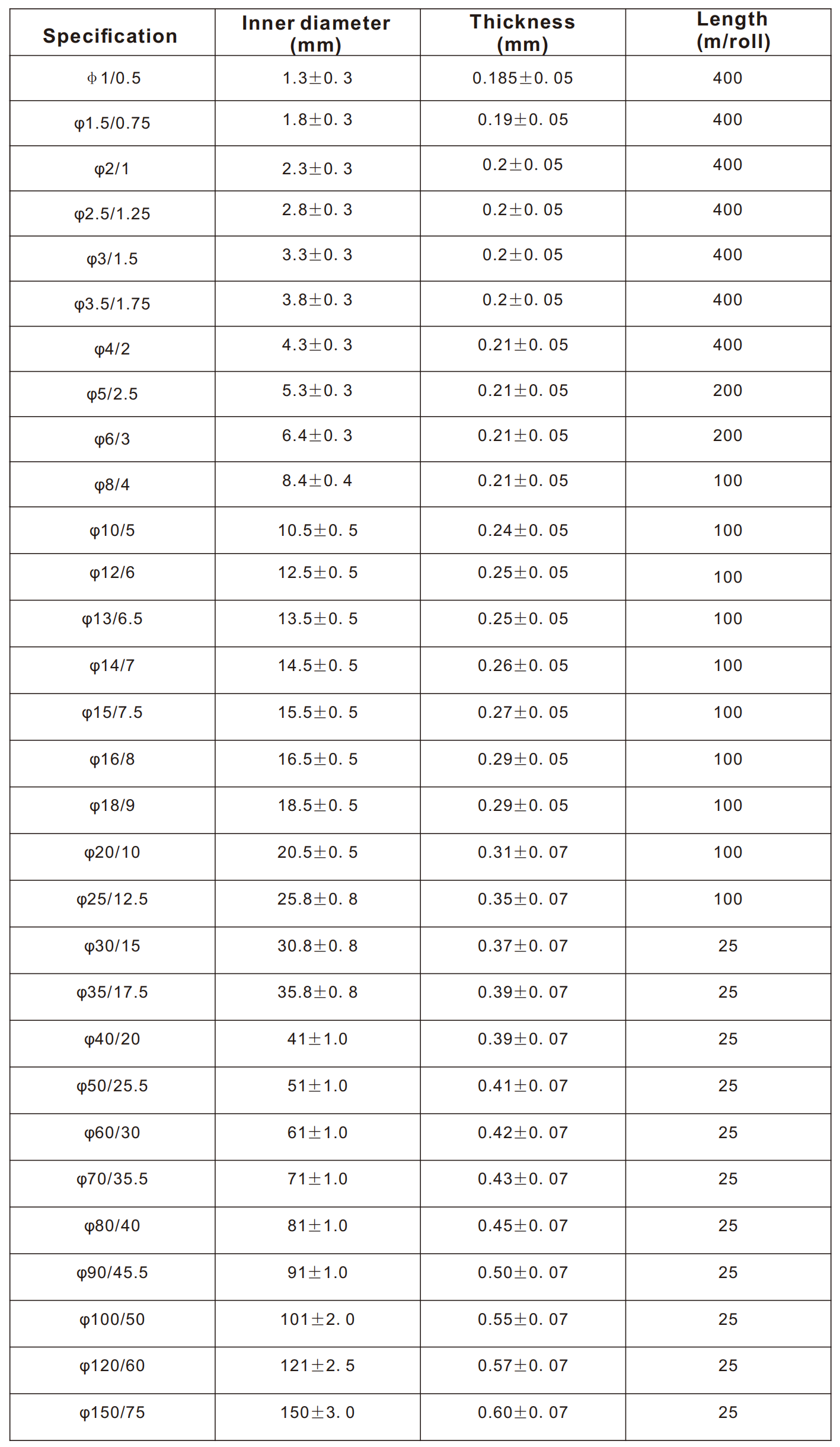

Ⅳ. Selection table for Low-Voltage Heat Shrink Tubing