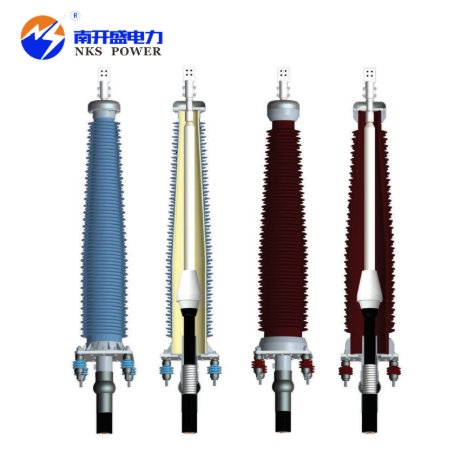

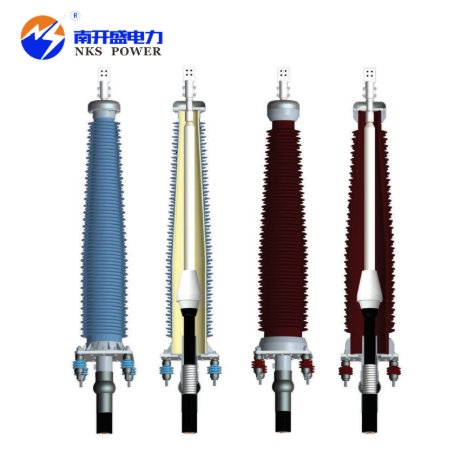

When you look at porcelain and composite High Voltage Cable Terminations, you notice big differences in how they work. Porcelain gives good electrical insulation but can crack if stressed. Composite types bend more easily and handle tough weather better. What you pick affects safety, how well it works, and how much it costs. Think about how long it lasts, how it works in different places, how it handles electricity, how easy it is to put in, and the price to choose what is best for you.

I. Durability

When you pick high voltage cable terminations, you should think about how long the insulators last. Porcelain insulators and composite insulators each have their own good and bad points. Knowing how each one works when stressed helps you choose the right one for your job.

a. Porcelain

Porcelain insulators have been used in the power industry for many years. You can find them in substations and on transmission lines. Their design helps them stand up to electrical stress, but their hard material can cause problems.

Mechanical Stress

Porcelain insulators are strong when squeezed. They can hold up heavy cables and equipment. But if you bend or hit porcelain, it can break. Porcelain is stiff and does not bend under pressure. If you drop a porcelain insulator, it might crack or break apart. You need

to be careful when handling porcelain insulators so they do not get damaged.

Breakage Risk

Porcelain insulators can break easily. Their hard material makes them likely to crack if hit or dropped. In places with lots of shaking or falling things, porcelain insulators might not last long. You may have to replace broken porcelain insulators more often, which can cost more money and time.

b. Composite

Composite insulators are made from polymer materials and fiberglass rods. This makes them better than porcelain insulators in tough places.

Flexibility

Composite insulators can bend and twist without breaking. This lets them take in shocks and shaking. When you use composite insulators, they are less likely to break if dropped or hit. They are also lighter, so they are easier to move and install.

Aging

All insulators get older, but composite insulators fight off many common problems. The outside layer keeps water and dirt away from the inside rod. Over time, composite insulators might look worn on the outside, but they almost never fail badly. You can count on composite insulators to work well for many years, even in rough places.

c. Practical Impact

Picking between porcelain insulators and composite insulators depends on what your project needs. If you need strong support and work in a calm place, porcelain insulators work well. If you deal with lots of shaking, hits, or drops, composite insulators last longer and break less. Here is a quick comparison:

Feature | Porcelain Insulators | Composite Insulators |

Weight | Heavy | Light |

Flexibility | Low | High |

Breakage Risk | High | Low |

Long-Term Durability | Good (if undamaged) | Excellent |

You should always pick the insulator that fits your work area. By knowing what porcelain and composite insulators do best, you can make your high voltage systems work better and need less fixing.

II. Environmental Performance

When you pick high voltage cable terminations, think about the weather. Some insulators work better in tough places. Good environmental performance means your system lasts longer. It also means you do not have to fix it as much. You want insulators that keep working in rain, sun, or dirty air.

a. Pollution Resistance

Insulators can have problems in dirty areas. Dust, salt, and chemicals can stick to them. When water mixes with dirt, electricity can leak. Porcelain insulators do not do well here. Their surface can soak up water. This makes it easier for electricity to jump across. You might see sparks or damage.

Composite insulators are better with pollution. Their outside layer keeps water and dirt away. This special surface stays dry and clean. You get fewer sparks and less chance of breaking. In dirty places, composite insulators work better for a long time. Tip: If your area is very dirty, use composite insulators for better results.

b. Weather and UV

Weather changes fast. Rain, snow, and sun can hurt insulators. Porcelain insulators can handle rain and snow. But if water freezes inside, they can crack. Sunlight can also make porcelain weaker over time.

Composite insulators are good with weather. They do not crack when it gets cold. Their surface keeps water off. They also block sunlight damage. Composite insulators work well in storms and strong sun. Here is a quick comparison:

Environmental Factor | Porcelain Insulator | Composite Insulator |

Pollution Resistance | Moderate | Excellent |

UV Resistance | Moderate | High |

Water Repellence | Low | High |

c. Harsh Climates

Some places are very cold, hot, or wet. Porcelain insulators can break in the cold. They can also crack if it gets cold fast. In hot, wet places, porcelain can have more sparks.

Composite insulators stay strong in bad weather. They bend and do not break in the cold. The outside layer keeps water and heat out. They work well even when the weather changes a lot.

In cold places, composite insulators do not crack.

In hot, wet places, they stop sparks.

In coastal areas, they block salt and water.

Think about where you will use your insulators. If you know how each type works in different weather, you can choose the best one for your high voltage cable terminations. Note: Pick the right insulator for your weather and pollution.

III. Electrical Performance

When you pick insulators for high voltage cable terminations, you must check how they handle electricity. Electrical performance is important for safety and for keeping your system working well. Porcelain insulators and composite insulators each have their own strengths. In modern networks, reliable power cable termination is essential to maintain insulation performance and prevent energy loss. Choosing the right termination system ensures stable operation and extends service life.

a. Insulation Properties

Porcelain insulators have been used for a long time. They are trusted to stop electricity from passing through. Their ceramic material blocks electricity very well. This gives them high dielectric strength. Porcelain insulators help keep your system safe from electrical problems.

Composite insulators have a fiberglass core and a polymer shell. These materials also stop electricity from leaking out. Composite insulators give good insulation, but their dielectric strength is usually a bit lower than porcelain. They still protect most high voltage systems well. Note: If you need the best insulation, porcelain insulators give the highest electrical performance.

b. High Voltage Stress

High voltage systems put a lot of stress on insulators. Porcelain insulators can handle sudden high voltages. They keep working even when the voltage jumps up fast. You can use them where you expect strong electrical stress.

Composite insulators also work well with high voltage. Their design spreads out the electrical field. This lowers the chance of flashover. Composite insulators work in most high voltage places, but porcelain insulators are better for the toughest jobs. Here is a quick table to compare:

Feature | Porcelain Insulators | Composite Insulators |

Dielectric Strength | High | Moderate |

Impulse Withstand | Excellent | Good |

Field Distribution | Good | Excellent |

c. Tracking and Erosion

Tracking and erosion can hurt insulators over time. Tracking happens when electricity moves along the surface. Erosion wears away the material. Porcelain insulators resist tracking, but dirt and water can cause problems. Over time, you might see marks or cracks.

Composite insulators do very well here. Their polymer surface keeps water and dirt away. This makes tracking and erosion less likely. They last longer and fail less in tough places. You should always choose the insulator that fits your system. By knowing how porcelain and composite insulators work, you can make your high voltage network safer and more reliable. Tip: In places with lots of dirt or water, composite insulators last longer.

Porcelain insulators: Strong electrical performance, but watch for surface damage.

Composite insulators: Great resistance to tracking and erosion, ideal for polluted or wet areas.

IV. High Voltage Cable Terminations: Application Guide

Picking the right high voltage cable terminations helps keep your power system safe and strong. You need to choose the insulator that fits your weather, how you install it, and what you want it to do. This guide helps you pick between porcelain and composite for different jobs. When making your choice, it’s also helpful to consult a high voltage cable termination manufacturer, as they can provide expert guidance on product performance and compatibility for your specific installation.

a. Porcelain Use Cases

Porcelain insulators work best in certain places. You should use porcelain when you need strong electrical insulation and support. Porcelain is good where the air is clean and the weather does not change much.

Common scenarios for porcelain:

Indoor substations: Porcelain is used inside buildings. There is less dust, water, and chemicals. This helps porcelain last longer.

Dry climates: Porcelain works well where there is little rain or wetness. You will not have many problems with surface damage.

Heavy-duty support: If your cables are heavy, porcelain gives strong support. Its hard shape holds up big equipment.

Long-term installations: Porcelain is good for projects that last many years. The ceramic does not get old fast if you protect it from being hit.

Table: When to Choose Porcelain

Scenario | Why Porcelain Works Well |

Indoor Substation | Low pollution, stable climate |

Dry Outdoor Location | Less risk of surface discharge |

Heavy Cable Support | Strong mechanical strength |

Long-Term Project | Durable if undisturbed |

b. Composite Use Cases

Composite insulators are good in tough places. You should use composite when there is dirt, bad weather, or you want easy setup. For example, Composite Casing Termination products are often used in these environments to improve reliability and prevent moisture ingress, especially in outdoor or coastal applications.

Best scenarios for composite:

Outdoor installations: Composite insulators stand up to rain, snow, and sun. You can use them outside where weather changes a lot.

Polluted environments: If your site has dust or salt, composite insulators keep working. Their special surface keeps water and dirt away, so there are fewer sparks.

Remote or elevated sites: Composite insulators are light. You can carry and put them in without big machines.

Areas with vibration or movement: Composite insulators bend and take in shocks. They do not break easily where things move or shake.

Projects needing fast installation: You can finish jobs faster with composite insulators. You need fewer people and less equipment.

Tip: Pick composite insulators for high voltage cable terminations in new power systems, especially if you want less fixing and more dependability.

Table: When to Choose Composite

Scenario | Why Composite Works Well |

Outdoor/Remote Location | Weather and UV resistance |

Polluted Area | Hydrophobic, resists tracking |

High Vibration | Flexible, absorbs shocks |

Fast Installation Needed | Lightweight, easy to handle |

Coastal/Industrial Site | Blocks salt, chemicals, moisture |

c. Selection Factors

You need to think about a few things before picking porcelain or composite for high voltage cable terminations. Every job is different. Match the insulator to your weather, how you put it in, and what you want in the long run.

Key selection factors:

Environmental Conditions

Look at how dirty, wet, or hot and cold your area is.

Porcelain is best for clean, dry, and steady weather.

Composite is better for dirty, wet, or wild weather.

Mechanical Requirements

Think about how much weight your cables have.

Porcelain is strong for heavy things.

Composite bends and takes shocks well.

Installation and Maintenance

Think about how easy it is to move and set up insulators.

Composite is light and saves time and work.

Porcelain needs careful handling and more tools.

Electrical Performance

Check how much insulation and voltage you need.

Porcelain gives higher dielectric strength for important systems.

Composite stops tracking and damage in tough places.

Cost and Availability

Compare how much you pay at first and over time.

Composite usually costs less to buy, ship, and fix.

Porcelain may cost more at first and needs more checks.

Checklist for Choosing Insulators:

Is your area dirty or clean?

Do you need strong support for heavy cables?

Is quick setup important for your job?

Will your insulators face bad weather or shaking?

Do you want to spend less on fixing them later?

You make the best choice for high voltage cable terminations when you match the insulator to your weather, how you put it in, and your budget. Always ask experts if you have special needs or hard problems.

V. Conclusion

You now know the big differences between porcelain and composite high voltage cable terminations. Porcelain works well for strong electrical needs in clean, steady places. Composite is lighter and easier to put in. It also stands up better to dirt and bad weather. Most new business projects use composite insulators because they give more value. Always check what your site needs and ask experts before you decide.