I. Introduction: The Role of High Voltage Cable Terminations in Modern Power Systems

In every electrical power system, the connection between high voltage cables and equipment determines how safely and efficiently energy is transmitted. One of the most crucial components in this process is the High Voltage Cable Termination. Designed to connect and seal the end of a high voltage cable, this component ensures electrical insulation, mechanical protection, and long-term system reliability.

For B2B buyers in sectors such as utilities, renewable energy, heavy industry, and infrastructure, understanding how a high voltage termination functions is not just a technical detail—it’s a business-critical consideration. Whether you are setting up new substations, upgrading transmission lines, or maintaining large-scale installations, the performance of your high voltage termination system directly affects safety, uptime, and operational cost.

A well-engineered High Voltage Termination guarantees that energy can be transmitted without electrical leakage or partial discharge. It bridges the gap between flexible cable systems and rigid electrical equipment, enabling consistent performance even under extreme conditions. This makes it an essential element in any power distribution network.

II. Understanding High Voltage Cable Terminations

1. Definition and Basic Function

A High Voltage Cable Termination is the assembly that connects the end of a high voltage cable to electrical devices such as transformers, switchgear, or overhead lines. It provides an insulated interface that allows the conductor to safely transfer electrical energy into or out of the cable.

At its core, the termination performs three primary functions. First, it insulates the live conductor from the surrounding environment, preventing flashovers or arcing. Second, it offers mechanical protection by shielding the delicate internal structure of the cable from moisture, contamination, and physical damage. Finally, it manages electrical stress, distributing voltage gradients evenly across the cable insulation to avoid concentration at any one point.

Without proper termination, even the highest-quality cable can fail prematurely due to stress concentration or insulation breakdown. This makes the termination a fundamental safety and reliability component within every high voltage system.

2. Components of a Typical High Voltage Cable Termination

A typical power cable termination consists of several key parts, each designed to perform a distinct role in the insulation and stress management process.

Insulating Layer: Provides the main dielectric barrier between the conductor and the environment.

Stress Control Tube: Regulates the electric field around the cable end, preventing localized overstress.

Sealing and Protection System: Keeps out contaminants and ensures the connection remains moisture-proof.

Grounding Components: Maintain electrical safety and direct any leakage current safely to the ground.

These parts work together to ensure that the termination performs reliably over years of continuous service. Modern cable insulation systems rely on advanced polymeric materials and carefully engineered interfaces to achieve maximum electrical endurance and safety.

III. How a High Voltage Cable Termination Works

1. The Process of Energy Transfer

When electrical energy travels through a high voltage cable, it is enclosed within layers of insulation that control the electric field. At the termination point, these layers must transition smoothly into the external environment without losing insulation effectiveness.

A High Voltage Cable Termination achieves this by controlling the distribution of electric stress at the cable end. The stress control components and insulation materials ensure that the electric field gradually diminishes as it approaches the exposed area. This prevents any abrupt voltage change that could cause discharge or breakdown.

In practical terms, the termination acts as both a mechanical and electrical bridge. It allows the conductor to connect to equipment terminals while maintaining consistent dielectric performance. The integrity of this connection defines how efficiently the system can transfer power and how long it can operate without maintenance.

2. Managing Electrical Stress and Heat

One of the major engineering challenges in high voltage systems is electrical stress management. If the electric field intensity becomes too high at any point along the termination, it can lead to insulation degradation, tracking, or even catastrophic failure.

To counter this, terminations are designed with stress relief cones, tapes, or tubes that regulate field distribution. These components ensure the voltage gradient remains uniform, allowing safe and stable operation. In addition, heat generated during current flow must be dissipated efficiently to prevent localized overheating.

Effective heat dissipation and stress management are the foundation of a durable high voltage termination system. By maintaining stable thermal and electrical conditions, these designs extend the lifespan of the entire power cable insulation network. In addition to traditional polymeric designs, new configurations such as Composite Casing Termination have become increasingly popular in modern high voltage systems. These terminations combine lightweight structure with superior mechanical strength and insulation performance, making them suitable for environments that require both durability and compact installation.

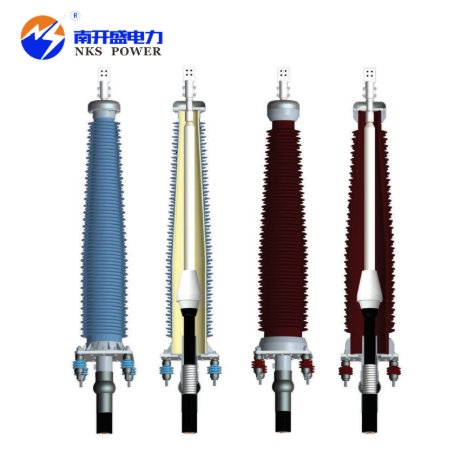

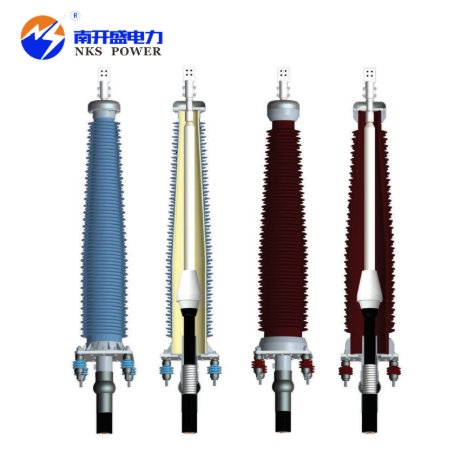

IV. Types of High Voltage Cable Terminations

1. Indoor vs. Outdoor Terminations

High voltage terminations can generally be classified as indoor or outdoor, depending on their installation environment.

Indoor terminations are installed within substations, control rooms, or enclosed electrical spaces where they are protected from weather exposure. These designs focus primarily on electrical insulation and compact construction.

Outdoor terminations, on the other hand, must endure direct sunlight, rain, dust, and temperature fluctuations. Therefore, they include additional sealing, UV protection, and weather-resistant features. Proper installation of outdoor models ensures reliable operation even in harsh climates.

Choosing between indoor and outdoor terminations depends largely on the project’s environmental conditions and the physical location of the cable connection. For example, in open-field substations or renewable energy sites, outdoor high voltage cable termination solutions provide the necessary environmental resilience.

2. Dry, Heat Shrink, and Cold Shrink Terminations

Another common classification method is based on installation technology. The three most widely used types are dry, heat shrink, and cold shrink terminations.

Dry Terminations: Utilize pre-molded components that do not require heating or special tools. These are often favored for quick installation and reduced site complexity.

Heat Shrink Terminations: Employ heat-activated materials that conform tightly to the cable when exposed to controlled heat, providing robust sealing and insulation.

Cold Shrink Terminations: Made from elastomeric tubes that shrink into place when the supporting core is removed, creating a precise, tool-free seal.

Each type offers specific advantages depending on the installation environment, cable design, and required maintenance level. For B2B buyers planning large-scale electrical infrastructure projects, selecting the appropriate high voltage cable termination kit ensures both safety and long-term performance.

V. Installation Considerations for B2B Applications

1. Site Preparation and Environmental Factors

Installing a High Voltage Cable Termination requires precision, expertise, and controlled conditions. Before beginning, the site must be clean, dry, and free of contaminants such as dust or moisture. Any impurity introduced during installation can compromise insulation integrity, leading to future performance issues.

Environmental conditions play a crucial role as well. Extreme humidity or temperature fluctuations can affect material behavior during the assembly process. Proper site preparation helps maintain consistent installation quality across different projects and environments.

In B2B contexts—such as power utilities, oil and gas facilities, or manufacturing plants—these factors are particularly critical. A well-prepared installation environment directly impacts the reliability of the power distribution system, minimizing downtime and service interruptions.

2. Skilled Technicians and Quality Assurance

Even the best materials and designs can fail if the termination is not installed correctly. That is why qualified technicians and comprehensive quality assurance procedures are essential.

Professional installers understand how to manage cable stripping, insulation alignment, and component assembly with precision. They ensure that stress control elements are positioned accurately, and sealing components are properly compressed. This expertise reduces the risk of air gaps or misalignment that could lead to partial discharge.

Furthermore, post-installation testing—such as insulation resistance checks and visual inspection—helps confirm that the cable termination quality meets international standards. Many B2B buyers also require detailed documentation and certification to verify that the installation complies with electrical safety regulations.

Partnering with experienced engineers and suppliers ensures that every High Voltage Termination performs as intended, delivering consistent power transmission for years to come. In large-scale projects, the collaboration between suppliers, contractors, and maintenance teams is the foundation of long-term reliability and operational safety.

VI. Common Issues and How to Prevent Failures

1. Typical Problems in High Voltage Cable Terminations

Even with proper materials and design, High Voltage Cable Terminations can face challenges during their service life. Common issues often arise from improper installation, material degradation, or environmental exposure. Among the most frequent problems are partial discharge, insulation tracking, moisture ingress, and mechanical stress at connection points.

Partial discharge typically occurs when air gaps or impurities exist within the insulation layers. Over time, these micro-discharges erode the material, reducing dielectric strength and eventually leading to breakdown. Similarly, tracking—the formation of conductive paths along insulation surfaces—can occur in humid or polluted conditions.

Another common issue is moisture ingress. If sealing components are not correctly installed, water or humidity can enter the termination, lowering insulation resistance and promoting corrosion. Additionally, excessive mechanical stress caused by cable movement, vibration, or thermal expansion can loosen joints and reduce performance reliability.

These problems may not be immediately visible but can progressively compromise the entire power distribution system, resulting in unplanned outages and high maintenance costs for B2B operators.

2. Preventive Measures and Maintenance Practices

Preventing termination failures begins with correct installation procedures and routine inspection. Following standardized installation steps, using clean tools, and maintaining controlled conditions are vital to avoid early defects.

B2B buyers should also ensure that installation technicians are trained according to international best practices. Using proper stripping tools, avoiding overbending, and checking for uniform sealing are small steps that yield major benefits in long-term reliability.

Regular maintenance inspections can identify early signs of degradation—such as discoloration, surface cracking, or corona activity—before they evolve into severe failures. It’s also recommended to perform periodic cable joint and termination testing, including partial discharge measurements, to ensure system integrity.

By adopting a proactive maintenance strategy, industrial operators can significantly extend the lifespan of their High Voltage Termination systems, reducing downtime and ensuring stable energy delivery across facilities or transmission networks.

VII. Choosing the Right High Voltage Termination for Your Project

1. Key Factors for B2B Buyers

Selecting the right High Voltage Cable Termination involves more than matching voltage ratings or insulation materials. For B2B buyers managing complex electrical systems, the decision should balance technical compatibility, operational environment, and long-term service goals.

When evaluating options, consider the installation environment—whether indoor, outdoor, coastal, or industrial. Harsh outdoor conditions require terminations with superior weather resistance and sealing properties. In contrast, indoor setups may prioritize compact design and ease of installation.

Another critical factor is insulation compatibility. The termination material must align with the type of cable insulation, such as XLPE or EPR, to ensure consistent dielectric performance. B2B buyers should also evaluate mechanical strength, thermal endurance, and ease of maintenance during procurement.

In addition, compliance with international quality standards—such as IEC or IEEE guidelines—offers assurance of tested reliability. Ensuring that products meet these standards can protect the project from potential downtime and warranty issues.

Ultimately, the goal is to select a termination that fits both the technical specifications and operational demands of the system, ensuring safe, stable, and efficient energy flow throughout the facility.

2. Working with Trusted Suppliers

For B2B procurement, the quality of a High Voltage Cable Termination depends heavily on the expertise of the supplier or manufacturer. A reliable supplier not only provides certified components but also offers technical guidance, installation training, and after-sales support.

When choosing a partner, look for high voltage cable teimination manufacturer who demonstrate a clear understanding of industrial power systems and can tailor solutions to your project’s environmental and electrical requirements. This partnership approach helps ensure that the termination system performs optimally throughout its service life.

Additionally, working with suppliers that maintain strong quality control and testing capabilities ensures every unit undergoes rigorous inspection before shipment. This reduces on-site rework and guarantees that installations meet both internal and external compliance standards.

By prioritizing collaboration with trusted termination suppliers, B2B companies can secure a more reliable and cost-effective long-term solution for their high voltage infrastructure.

VIII. Future Trends in High Voltage Termination Technology

As energy systems evolve, so does the technology behind High Voltage Cable Terminations. The demand for renewable energy integration, smart grid development, and sustainable manufacturing practices is driving continuous innovation in cable termination design.

1. Emerging Materials and Smart Design

Modern terminations are increasingly using advanced polymer materials that provide better resistance to heat, UV radiation, and mechanical stress. These innovations enhance lifespan and performance stability in demanding outdoor environments.

Additionally, the development of smart monitoring systems integrated into cable accessories allows for real-time health assessment. Sensors can detect temperature fluctuations, partial discharges, and moisture presence—helping maintenance teams take action before issues escalate.

2. Sustainability and Green Manufacturing

Sustainability is becoming a key concern in B2B procurement. Manufacturers are now focusing on eco-friendly materials and energy-efficient production processes to reduce carbon footprints. Recyclable insulation compounds and modular designs make future upgrades easier, aligning with global environmental objectives.

The combination of advanced materials, intelligent monitoring, and sustainable practices represents the next generation of High Voltage Termination technology—where performance meets responsibility.

IX. Conclusion: Building Reliability Through Proper Cable Termination

The performance of a power network depends not only on the quality of cables and transformers but also on the integrity of every High Voltage Cable Termination. As a critical link in the chain, it ensures that electrical energy is transmitted safely and efficiently across industrial, utility, and commercial applications.

For B2B buyers, understanding how terminations work and knowing what to look for during selection, installation, and maintenance can significantly improve project reliability. The right termination system—properly installed and regularly inspected—prevents power loss, minimizes risk, and extends asset lifespan.

In a world increasingly reliant on uninterrupted energy supply, investing in quality High Voltage Cable Terminations is a practical step toward operational excellence. By partnering with experienced suppliers and adhering to engineering best practices, organizations can ensure consistent, safe, and sustainable power performance for years to come.