Ⅰ. Introduction to 220 Epoxy Resin Bushing

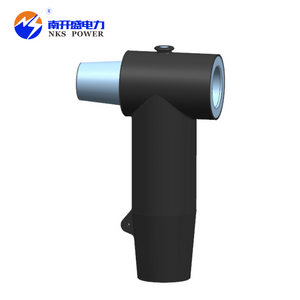

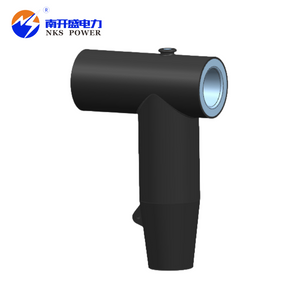

The 220kV epoxy resin bushing is the core insulation component carefully developed by our company for gas-insulated ring main switchgear, GIS. As a vital connection and isolation component in power transmission and distribution systems, it perfectly performs a dual role: guiding high voltage current through the grounding cabinet as well as ensuring total airtightness of the equipment.

This is achieved by using high-quality epoxy resin and forming through the advanced APG process; hence, a perfect insulation structure without any voids and gaps can be attained. It can serve ratings up to 220kV for very critical applications like high voltage switchgear, transformer, and GIS switchgear, which would be the basic element in creating a modern highly reliable smart grid. We are an epoxy resin bushing manufacturer who has been applying quality control to the raw material all the way to finished product shipment so that every bushing would have excellent electrical characteristics with long mechanical life to meet all the highest requirements from stability and safety of power customers in the world.

Ⅱ. Feaures of 220 Epoxy Resin Bushing

1. Great Electrical Insulation Properties

High dielectric strength: Epoxy resin material has a very high dielectric constant and breakdown voltage. It can operate at voltages of 220 kV and above, as well as with different transient overvoltage surges; thereby, absolute insulation reliability in extreme electrical environments is ensured.

Arc Resistance: Arc resistance of the bushing surface is excellent, which prevents flashover accidents due to surface creepage so that continuous and stable running of equipment can be ensured.

2. Extraordinary Mechanical Strength and Stability

Great Strength in Mechanics: The epoxy bushing has a dense structure and expresses very high resistance to bending, compression, and impact. It will take outside mechanical forces-bus bar stress, wind load, earthquake-without failing performance by going through any sort of deformation.

Great dimensional stability because the thermal expansion coefficient is low and dimensions remain stable at different temperature environments, therefore there will be no seal failure or internal stress cracking due to any thermal cycling. Excellent resistance to weathering and aging.

3. Outstanding Weather Resistance and Aging Resistance

Extreme Resistance to Corrosion: Epoxy resins by nature are resistant to chemical attack-acids, alkalis, and salts-plus humid, dirty atmospheres. No special maintenance is required for it and particularly not suited for use in highly corrosive areas such as coastal regions and industrial zones.

Great Water-Retention Ability: The surface of the material shows great water-retention ability, letting rainwater drop off and resisting forming a continuous water film. This greatly increases flashover resistance in wet and dirty conditions.

4. Accurate Sealing and Joining Plan

Solid Gas Tightness: The bushing flange and insulator are molded as one, paired with an advanced sealing groove plan, making sure there is no leakage of SF6 insulating gas inside the GIS gear, keeping perfect insulation inside the switchgear.

Easy Linkup Designs: To help join the switchgear and other electric parts, standard link forms (like threaded holes and main wires) are made on both ends of the cover, making sure it is simple to set up and has strong links.

Ⅲ. Electrical Performance Parameters of 220 Epoxy Bushing

NKS-EB-24/1250- | Description | 1# 220 Epoxy Bushing | 2# 220 Epoxy Bushing | 3# 220 Epoxy Bushing |

| Technical Parameters | System Voltage | 12/24kV | 12/24kV | 12/24kV |

Rated current | 630A | 630A | 1250A |

Frequency withstand voltage(AC) | 68kV/1min |

Partial Discharge | 26.4kV<5pC |

Impulse voltage | 125kV ±10times |

Capacitance value

| 18±3PF

| 18±3PF | 26±3PF |

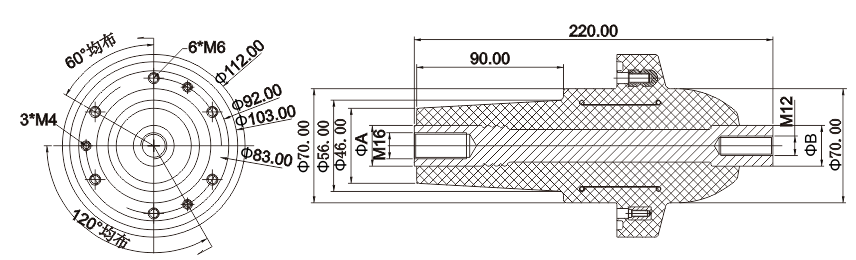

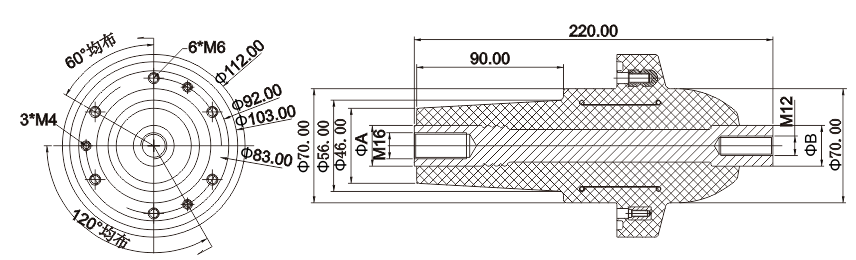

| Size of the conductive rod |

| A | Φ25 | Φ30 | Φ30 |

| B | Φ25 | Φ25 | Φ30 |

The product has passed the inspection and certification of the China Electric Power Research Institute (CEPRI) Power Industry Electrical Equipment Quality Inspection and Testing Center

Type test reference standard: IEC 60502-4:2010 GB/T 12706.4-2008