I. Introduction: The Role of Elbow Connectors in Modern Cable Systems

Today, in industrial and commercial environments, cable systems have become increasingly complex. Whether in manufacturing plants, data centers, or construction projects, cables must be routed efficiently and securely to ensure reliable electrical or data transmission. However, as systems expand and space constraints tighten, maintaining orderly cable management presents a growing challenge. This is where the Elbow Connector plays a pivotal role. More than a mechanical accessory, it protects cables from sharp bends, mechanical strain, and environmental exposure. Its role extends beyond mere functionality; it enhances system reliability, safety, and long-term durability.

For B2B buyers managing industrial infrastructure or commercial installations, choosing the right elbow connector is not a trivial decision. The connector’s material, design, and compatibility determine not only how efficiently cables perform but also how easy future maintenance will be. A poor selection could result in premature cable wear, signal interference, or costly downtime. Therefore, understanding the fundamental aspects of elbow connectors—and how to select the right one—is critical for achieving consistent performance in complex cable systems.

With this understanding, let’s explore the essential factors that guide the selection of the most suitable elbow connector for your application.

II. Understanding What an Elbow Connector Does

A. Core Function in Cable Routing

At its core, the Elbow Connector simplifies cable routing by enabling directional transitions in tight or confined spaces. In many industrial settings, cables must navigate around machinery, panels, or architectural obstacles. Without a proper elbow connector, sharp cable bends could lead to insulation cracks, reduced flexibility, and signal degradation.

By maintaining a controlled bend radius, an elbow connector ensures cables remain structurally sound and functionally reliable. This is especially important in systems carrying power or data, where even minor physical stress can disrupt signal integrity. The connector essentially acts as both a guide and a shield—directing the cable flow while protecting it from environmental and mechanical hazards.

In structured cabling systems, the correct elbow connector contributes to overall network reliability, reduces cable fatigue, and enhances long-term system stability. For B2B buyers, such reliability translates directly into minimized downtime and reduced maintenance costs.

B. Common Applications Across Industries

Elbow connectors are indispensable in numerous sectors. In industrial automation, they route power and signal cables within machinery, ensuring clean layouts and efficient space use. In power distribution, they connect conduits in switchgear or control panels, preventing overstress at sharp corners. In telecommunications, elbow connectors safeguard signal lines against strain in dense wiring environments. Similarly, in construction, they offer secure passage for electrical conduits through walls and tight spaces.

Across these sectors, the recurring demand from B2B clients is clear—durability, adaptability, and protection. The right elbow connector not only fits mechanically but also withstands harsh operating conditions such as vibration, moisture, and temperature fluctuation. In medium-voltage power distribution systems, a Loadbreak Elbow Connector is often used to enable safe connection and disconnection under load conditions, providing flexibility and protection for maintenance operations in industrial environments.

C. Key Benefits for Business Operations

When integrated properly, elbow connectors bring tangible business benefits. First is safety—well-sealed connectors prevent exposure to live conductors and environmental hazards. Second is efficiency—they allow for quick installation and easy replacement during system upgrades or maintenance. Third is operational continuity—by minimizing cable strain, elbow connectors reduce the likelihood of cable failure, ensuring stable operations.

For B2B buyers managing long-term infrastructure, these advantages align directly with cost-effectiveness. Reduced maintenance frequency, simplified cable routing, and improved system scalability all contribute to greater return on investment.

III. Different Types of Elbow Connectors

A. Based on Material Composition

The material composition of an elbow connector greatly influences its performance and durability. Metal elbow connectors—commonly made from stainless steel, brass, or aluminum—are preferred in industrial environments where mechanical strength and corrosion resistance are vital. These connectors offer excellent grounding capability and withstand exposure to oils, chemicals, or high temperatures.

On the other hand, plastic elbow connectors—typically crafted from PVC or nylon—offer lightweight versatility and are suitable for less demanding conditions. Their insulation properties make them ideal for indoor, low-impact environments, especially in telecommunications or control panels.

The choice between metal and plastic depends largely on environmental exposure, safety requirements, and ease of installation. In moisture-rich or corrosive conditions, metal variants offer superior longevity, while plastic types may be ideal where weight reduction and electrical insulation are priorities. For example, a PT Elbow Connector is often preferred in pneumatic or threaded conduit systems, offering both reliable sealing and mechanical strength in demanding industrial conditions.

B. Based on Connection Mechanism

The connection mechanism also defines usability and maintenance flexibility. Threaded elbow connectors are widely used for secure, vibration-resistant fittings in industrial settings. Compression connectors provide airtight and watertight seals—making them valuable in environments exposed to dust or moisture. Meanwhile, push-in connectors deliver fast assembly and disassembly, preferred for applications requiring frequent cable changes or prototyping.

B2B buyers should evaluate not only the connection type but also the system’s long-term needs. If reusability and maintenance cycles are frequent, a push-in or compression connector may provide better operational efficiency. Conversely, where stability and sealing are priorities, threaded connectors remain a dependable choice.

C. Based on Angle and Design

Design and angle determine how well an elbow connector integrates within limited spaces. 90-degree elbow connectors are most common, guiding cables around sharp turns while maintaining integrity. 45-degree connectors are used when smoother directional transitions are needed without restricting cable movement.

Design choice can also impact cable aesthetics and routing orderliness, particularly in visible or customer-facing installations such as data centers or control panels. For compact enclosures or equipment with space constraints, the right angle design prevents interference and ensures a clean, professional layout.

IV. Factors to Consider When Choosing an Elbow Connector

A. Compatibility with Cable Type

Cable compatibility is the foundation of connector performance. The connector must align with the cable’s diameter, insulation type, and material. Mismatched dimensions can cause poor sealing, signal leakage, or even physical cable damage.

When evaluating compatibility, buyers should also consider the connector’s internal geometry to ensure proper clamping and strain relief. For instance, a tight-fitting elbow connector provides mechanical stability, while a poorly matched one may lead to slippage or deformation over time. In a well-engineered cable system, each connector complements the cable’s structure to maintain secure and consistent electrical contact.

B. Environmental Conditions

Environmental stressors such as temperature, humidity, and vibration heavily influence connector performance. In factories, outdoor installations, or marine applications, connectors face dust, moisture, or corrosive agents that can degrade materials over time. Therefore, choosing connectors with adequate sealing and protective coatings is critical.

For example, in heavy-duty industrial plants, connectors exposed to heat or chemicals require robust construction and corrosion-resistant finishes. In outdoor telecommunications systems, weatherproof elbow connectors help maintain continuous operation despite environmental fluctuations.

Considering the installation environment early in the selection process helps prevent failures and reduces maintenance demands over the connector’s lifespan.

C. Installation and Maintenance Requirements

Ease of installation often determines how efficiently a project can progress. Elbow connectors designed with ergonomic features—such as easy-grip surfaces or quick-fit designs—significantly reduce labor time during assembly. In large B2B projects, small gains in installation speed can translate into substantial cost savings.

Similarly, maintenance accessibility is crucial. Systems that require periodic inspection or cable replacement benefit from connectors that allow convenient reassembly without damaging components. Choosing the right connector not only simplifies installation but also supports long-term serviceability, minimizing downtime during scheduled maintenance.

D. Safety and Compliance Standards

Safety compliance should never be compromised in connector selection. B2B buyers must prioritize products that conform to recognized international safety and quality standards, ensuring they meet performance expectations under diverse operating conditions. Certified connectors guarantee consistent reliability, insulation strength, and material integrity.

For buyers in regulated industries—such as energy, automation, or telecommunications—using compliant elbow connectors protects both personnel and equipment. In addition, adherence to standards enhances brand credibility and reduces liability risks associated with electrical faults or system failures.

V. The Importance of Material and Build Quality

A. Corrosion Resistance and Durability

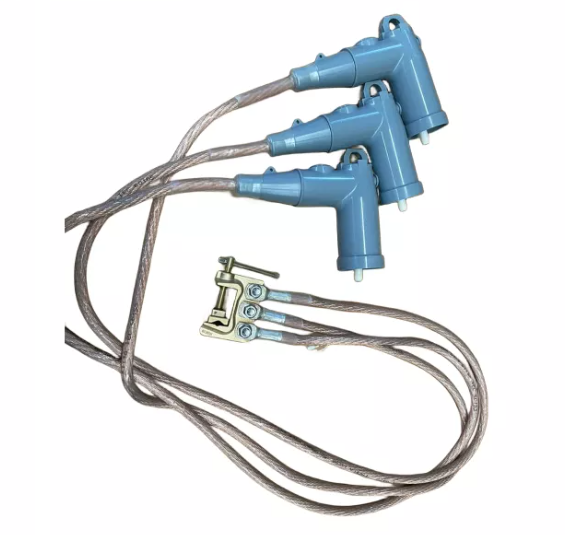

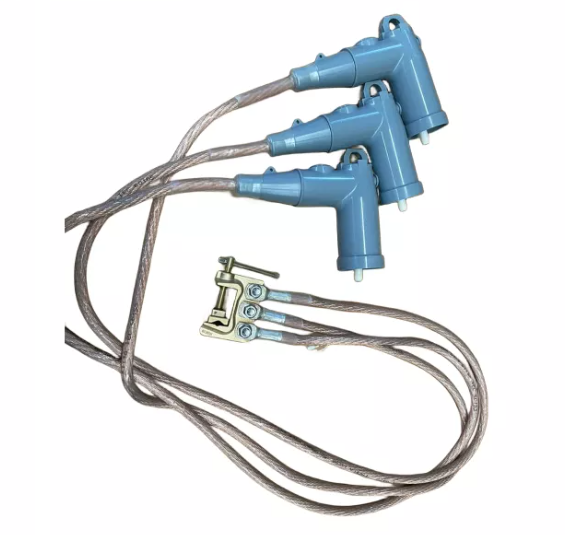

Material and build quality are often decisive factors in the long-term success of cable installations. Elbow connectors exposed to moisture, chemicals, or mechanical vibration must possess corrosion resistance and mechanical toughness. High-quality materials resist environmental wear, extending service life and ensuring stable operation even under demanding conditions. A Ground Elbow Connector is commonly applied in grounding systems where mechanical robustness and corrosion resistance are crucial to ensure reliable fault protection and system safety.

Durable connectors also prevent degradation that could compromise safety. For example, a corroded connector may increase electrical resistance or weaken structural stability. In B2B settings, where reliability directly impacts operational uptime, investing in durable components is a strategic decision that safeguards long-term performance.

B. Conductivity and Insulation

In electrical systems, both conductivity and insulation determine how safely and efficiently power or signals are transmitted. The internal materials of an elbow connector influence its ability to conduct electricity without loss, while the outer housing must prevent current leakage. Poor insulation or low-quality materials can lead to overheating or short circuits.

For sensitive communication or control systems, insulation quality also contributes to signal clarity. Well-constructed elbow connectors minimize electromagnetic interference and ensure stable transmission over time. As such, selecting connectors with proven insulation and conductivity properties enhances overall system efficiency and reliability.

VI. Installation Best Practices for Elbow Connectors

A. Pre-Installation Preparation

Proper installation begins long before the connector is fitted. Each cable and connector should be inspected for defects, such as cracks or contamination, that could compromise the seal. Cleaning surfaces and verifying correct alignment ensures a tight and reliable connection.

During assembly, applying appropriate torque control prevents over-tightening that might damage threads or seals. For B2B installation teams managing large projects, standardized preparation procedures reduce variability and promote consistent quality across all installations.

B. Proper Cable Routing and Strain Relief

After connection, cable routing requires equal attention. Avoiding excessive bending or mechanical tension preserves cable integrity and prevents premature wear. Maintaining the manufacturer-recommended bend radius ensures optimal performance, especially in data or signal lines where physical stress could affect transmission.

Effective strain relief prevents the connector from bearing cable weight or tension, thereby reducing fatigue and extending system longevity. These best practices are essential for achieving a professional, reliable installation in any industrial or commercial environment.

C. Post-Installation Checks

Finally, after installation, performing thorough continuity and insulation tests verifies that the connector and cable are properly integrated. Labeling and documenting connections also facilitate future maintenance and troubleshooting. A well-organized documentation system helps maintenance teams quickly identify connection points during repairs or upgrades, saving valuable time.

For B2B buyers and technical teams, adherence to these best practices ensures that every elbow connector contributes to a safe, efficient, and long-lasting cable infrastructure.

VII. Common Mistakes to Avoid When Selecting Elbow Connectors

Even experienced engineers and procurement teams can make avoidable errors when sourcing elbow connectors for complex cable systems. These mistakes often appear small at first but can lead to serious long-term consequences such as cable failure, reduced efficiency, or costly rework. Recognizing these pitfalls early ensures better performance and safety.

1. Ignoring compatibility between cable size and connector type.

Selecting an elbow connector that doesn’t match the cable’s outer diameter or insulation structure can cause weak sealing, slippage, or physical strain. Always verify that the connector’s dimensions and internal clamping system suit the cable type being used.

2. Overlooking environmental protection requirements.

A common oversight is choosing connectors that are not built to withstand the actual working environment. For instance, connectors without proper sealing can quickly degrade in outdoor or humid conditions. B2B buyers should evaluate exposure factors such as temperature, vibration, or chemical presence before finalizing any connector type.

3. Focusing only on cost instead of performance and longevity.

While price competitiveness is essential in B2B procurement, choosing the cheapest connector may result in premature failure or higher maintenance expenses later. Prioritizing long-term reliability and build quality delivers better total value.

4. Selecting non-compliant or uncertified components.

Connectors that do not meet industry standards or safety certifications pose serious risks, especially in regulated sectors like energy or automation. Always ensure that products comply with recognized safety and performance benchmarks.

Avoiding these common errors helps B2B professionals build a foundation of safety, quality, and efficiency throughout their cable systems.

VIII. Comparing Elbow Connectors with Other Connector Types

A. Straight vs. Elbow Connectors

Both straight connectors and elbow connectors have essential roles in cable system design. Straight connectors are typically used when cables can be routed in a direct line without spatial limitations. However, in compact or constrained layouts—such as control cabinets, machinery housings, or wall penetrations—elbow connectors provide the necessary flexibility to route cables safely without stress or obstruction.

The major advantage of an elbow design lies in space optimization. For B2B installations where aesthetics and orderliness matter—like in automation panels or data centers—elbow connectors contribute to cleaner, more professional layouts.

B. Fixed vs. Flexible Connector Designs

Another comparison arises between fixed and flexible connector designs. Fixed elbow connectors maintain a rigid angle and are ideal for stable installations where cable positions remain constant. Flexible connectors, however, offer adjustability and limited movement tolerance—useful for applications involving vibration or shifting components.

In industrial environments, where machinery may vibrate or move slightly during operation, flexible connectors reduce mechanical stress and prolong cable life. On the other hand, in stationary systems such as power distribution cabinets, fixed connectors ensure consistency and structural integrity.

Choosing between these types depends on project requirements. Evaluating mobility, vibration exposure, and space constraints ensures the connector type aligns perfectly with the application’s mechanical and operational needs. In certain modular systems, a Separable Connector may be used alongside an Elbow Connector to allow easier disconnection during maintenance without disturbing the overall cable routing.

IX. Tips for B2B Buyers When Sourcing Elbow Connectors

A. Working with Reliable Manufacturers

For B2B buyers, the selection of a reliable supplier is as critical as the product itself. A trusted manufacturer provides more than just hardware—they deliver technical expertise, consistent quality, and long-term support. When evaluating suppliers, consider their experience with industrial projects, their ability to provide engineering assistance, and their responsiveness to after-sales inquiries.

Requesting sample evaluation before mass orders is a practical way to verify material integrity, assembly precision, and overall performance. Reliable partners ensure the same product quality is maintained across large-scale or repeat orders, safeguarding your project timelines and operational continuity.

B. Customization and OEM Services

In complex B2B environments, off-the-shelf connectors may not always meet project requirements. Many leading manufacturers now offer custom or OEM elbow connector solutions—tailored to unique angles, materials, or environmental needs.

Customization allows project engineers to integrate connectors seamlessly into existing systems, optimizing both performance and aesthetics. For instance, in specialized machinery or enclosed systems, a custom connector design can improve cable routing efficiency while maintaining proper insulation and sealing.

Partnering with an OEM-capable supplier also opens opportunities for private labeling and consistent design integration across multiple projects. This helps large enterprises maintain uniformity and reliability across different facilities or equipment types.

C. Logistics and Long-Term Partnership

Beyond the product itself, supply chain reliability plays a decisive role in B2B success. A supplier with stable logistics capabilities can ensure on-time delivery and handle large or scheduled orders efficiently. This consistency helps project managers plan installations without delays or shortages.

Establishing a long-term partnership with a dependable connector supplier builds mutual trust and ensures product quality consistency across future projects. When both parties share technical insight and feedback, it creates a foundation for continuous improvement in cable system performance.

X. Conclusion: Building Reliable Cable Systems with the Right Elbow Connector

In every modern electrical or communication infrastructure, elbow connectors serve as critical links between safety, functionality, and long-term reliability. Their purpose extends far beyond simply joining cables—they ensure structural protection, maintain system order, and provide the flexibility needed to manage complex cable routing efficiently.

For B2B buyers, choosing the right elbow connector means balancing multiple factors: compatibility, environmental resilience, installation convenience, and compliance assurance. The right decision can significantly reduce maintenance downtime, enhance safety, and extend the overall lifespan of cable systems.

As technology advances, the elbow connector continues to evolve—embracing smarter materials, modularity, and sustainability. Businesses that prioritize quality and strategic sourcing will build more robust, efficient, and future-ready systems.

Ultimately, the Elbow Connector is not merely a small mechanical fitting—it is the foundation of dependable cable infrastructure. By investing in the right design, material, and supplier partnership, organizations ensure their systems remain secure, efficient, and ready for the challenges of tomorrow’s connected world.