I. Introduction

The proper installation of a busbar connector is a critical procedure that directly impacts the safety, efficiency, and longevity of an entire electrical power distribution system. These components are built for strength. Improper installation can create major dangers such as electrical arcing and overheating, even leading to total system failure. Whether dealing with a basic or more advanced busbar connector setup, following safety rules is a must. Here are five key safety tips that every electrician, engineer, and technician should use for safe and steady setup. When workers join in these habits, they lower risks and make sure that the electrical framework, backed by top parts from makers like NKS Power, runs at its best for many years.

II. The Foundation of Safety

A safe and successful installation starts long before the first tool is picked up. Adequate preparation is the best way of accident avoidance and getting a perfect job, involving condition verification, work planning, and assembling the right materials with correct information. Errors emanate in large quantities when installations are done without preparations. A planned approach minimizes surprises in the work and makes sure all workers know their roles and the dangers involved. It tunes the whole operation to a controlled, methodical process rather than a dangerous exercise. Before any physical work commences, a detailed risk assessment must be performed for the specific worksite.

1. Identify and Isolate All Energy Sources

The foremost step is to confirm all energy sources feeding the installation area. This includes not only the main busbar run but also any auxiliary circuits that might remain live. Use up-to-date single-line diagrams to trace all potential power sources. The assessment should clearly define the boundaries of the work area and identify any back-feeding possibilities that could endanger the crew.

2. Assess Physical and Environmental Hazards

Look beyond electrical dangers. Assess the workspace for ergonomic risks, such as awkward postures or heavy lifting involved in maneuvering busbar sections. Consider environmental factors like wet or damp conditions that could compromise insulation resistance or increase the risk of electric shock. Proper lighting and clear access paths are also crucial for safety.

III. Ensuring a Zero-Energy State

Take meticulous care in guaranteeing that the system is de-energized. Many accidents have occurred because there was an assumption that a circuit was dead without verification. Never omit this step, and never take any exception to it. Only under highly controlled and specialized circumstances should there be any consideration as an absolute last resort to work on live equipment; never for standard installations. A zero-energy state is mandatory. This protects both the installation team from electrocution and the installation itself from accidental short circuits caused by tools contacting live parts. A formal protocol of Lockout/Tagout is not suggestive; it is a required standard of safety. Systematic isolation and verification mean disconnection and isolation of all energy sources at their origin points systematically. After isolation, each point should be secured with a personal lock and tag of the individual placing hands on that particular system to work. After applying locks, testing for voltage absence is imperative using a known good working tester. The tester must be tested before and after on a known live source to prove its worthiness. This applies to every type of connection, whether you are installing a T-type screened top busbar connector or a main feeder.

IV. Correct Handling and Installation Techniques

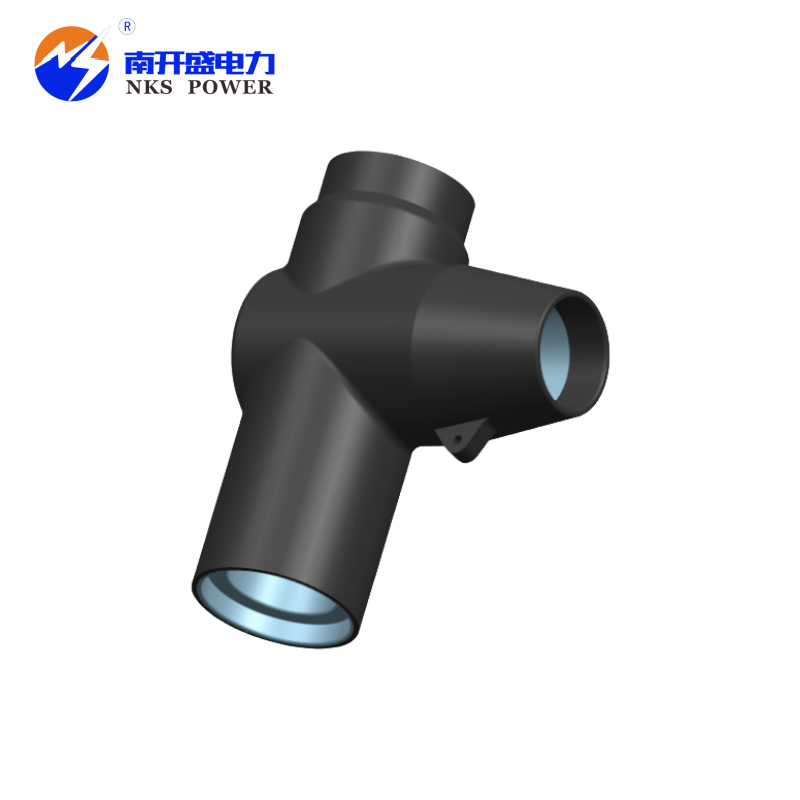

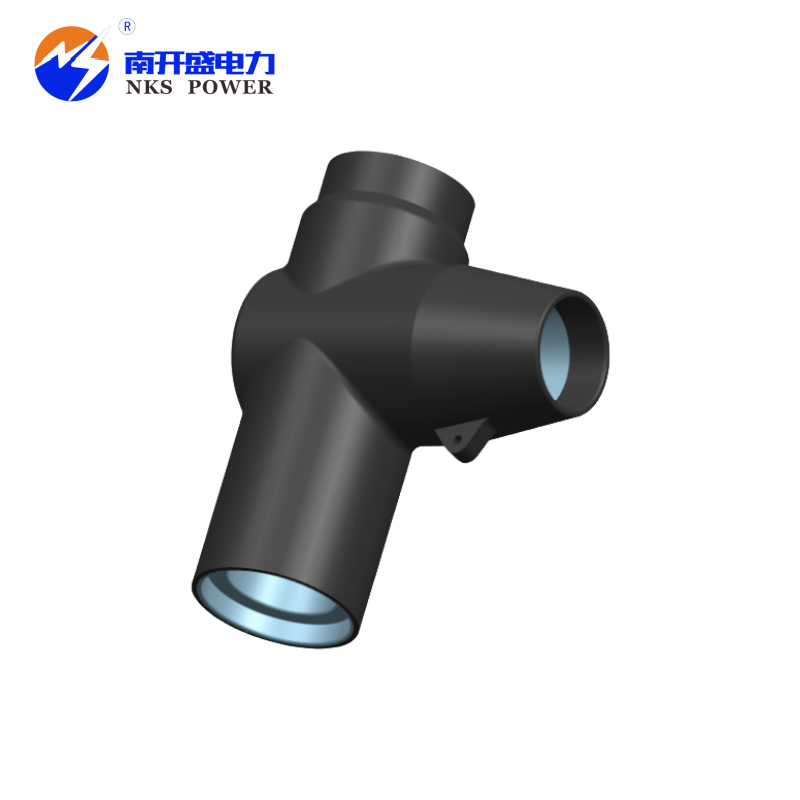

Right techniques used in the physical installation are key to immediate safety and long-term reliability. Mishandling can damage, and compromise the integrity of the component as well as create latent failure points. All types of connectors have specific installation requirements; Generic methods result in either contact pressure not being achieved, bolts being cross-threaded, or insulating surfaces being damaged. Manufacturer specific instructions go a long way in ensuring that the component performs as engineered. The integrity of a busbar connection hinges on achieving the correct mechanical pressure.

1. Proper Tool Usage and Torque Control

Always use the tools recommended by the manufacturer, such as insulated socket sets. Most critically, a calibrated torque wrench must be used to tighten connection bolts. Under-tightening can result in a high-resistance connection that will overheat, while over-tightening can strip threads, damage the busbar, or warp components, leading to a poor contact surface. The required torque value will differ between a robust U-type busbar connector system and a more delicate tubes-lug-type screened top busbar connector.

2. Careful Handling and Alignment

Busbars and connectors should be handled with care to prevent nicks or scratches that can concentrate electrical stress. When aligning components, avoid using excessive force. For example, when connecting a branch circuit using an unscreened top busbar connector, ensure the busbar is clean and the connector sits evenly before applying any torque to the bolts.

V. Maintaining Proper Clearance and Insulation

After securing the electrical connection, it becomes the next safety critical step to ensure proper insulation of all live parts and maintain adequate clearance as a way of guarding against flashover particularly when different types of connectors being installed at close distance from each other. The electrical enclosure should be arranged in such a manner that accidental contact between phases, between phase and ground, and with any other equipment is avoided. Proper spacing permits heat to dissipate and gives a safety margin for voltage surges.

1. Verify Phase-to-Phase and Phase-to-Ground Clearances

Design Standards Compliance The minimum required air clearance (shortest distance through air) and creepage distances (shortest path along a surface) are determined by international standards – for example, IEC based on the voltage level of the system. This is very important while installing a crossing type screened top busbar connector wherein different busbar runs cross over each other. The design should ensure that even under conditions of transient over-voltage, there is sufficient air gap to prevent an arc from forming between phases or to the grounded enclosure.

2. Inspect the Integrity of Insulation and Shielding

Check for Damage and Proper Seating, make sure that all insulating caps, sleeves, and barriers have been fully seated and are undamaged. For shielded connectors-for example a tubes lug type screened top busbar connector-it is critical to make sure that the shielding is properly grounded and also confirm the condition of insulating layers. Cracks or breaks in the insulation will create a path for tracking to develop into ultimately failure of the insulation-very dangerous shock hazard.

VI. Post-Installation Inspection and Testing

Work is not over until inspected and tested. This step demonstrates what has been accomplished and verifies that the place is indeed safe to receive power. If work at this stage is omitted, major mistakes will continue to go unnoticed. An inspection done in sequence uncovers things like tools left behind, loose parts, or improper assembly that may have crept into the job. Then, functional testing verifies the electrical soundness of the connection under a load that simulates normal control.

1. Perform a Detailed Visual and Mechanical Inspection

No power-on check shall be less than full. Go over every connection and make sure all bolts are properly torqued, lock washers engaged. Look for any signs of damage to insulation or shielding that might have occurred during the process of installation. Make sure all covers are on and there is not a single foreign item—wire clippings or tools—inside the box. Double-check to ensure that every connector, simple and fancy, is oriented and secured.

2. Conduct Insulation Resistance and Thermo-graphic Scans

After the visual inspection, electrical tests provide quantitative safety data. Use an insulation resistance tester (megger) to verify the integrity of the insulation between phases and between each phase and ground. A low reading could indicate damaged insulation or insufficient clearance. Once the system is energized, a thermo-graphic (infrared) scan under load is an invaluable non-contact method to identify hot spots caused by loose connections. This can reveal problems in a T-type screened top busbar connector that might not be visible to the naked eye.

VII. Conclusion

To install a busbar connector is a task, which requires readiness, precision, and consistency in the overt safety measures. The five tips discussed comprise adequate preparation, ensuring energy isolation, correct installation technique, proper clearances, and post-installation checking that creates a safety net. By treating these rules with due seriousness and rigor as actual laws-by doing so-this will not only ensure safety for the workers but also ensure reliability and the long life of the electrical system installation. Safety is never an accident; it has always been an option-in choosing to be safe by these rules-that marks one out as a skilled worker and an accountable practitioner.