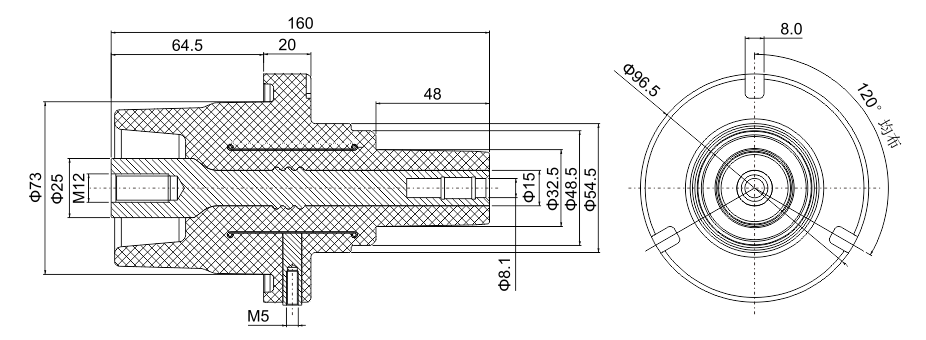

Ⅰ. Introduction to 160 Epoxy Resin Bushing

Docking bushing is mainly used in the inflatable ring networkcabinet, can effectively seal the insulation medium and support andfixed cable and copper row in the cabinet, can be connected to thequick power extraction device, rated current 250A, voltage level 12kV, the material of high quality epoxy resin and copper, usingnon-local induction network, can shield grounding or connected tolive display.

Ⅱ. Features of 160 Epoxy Resin Bushing

1. Reliable Cable Connection Solution

This product is specifically designed for the incoming and outgoing cable interfaces of SF6 gas-insulated ring main units, serving as the core component conncting the internal busbars to external cables. It provides a secure and efficient cable access point for various power distribution networks, ensuring stable power transmission.

2. Monolithic Epoxy Resin Insulation Technology

Employing advanced Automatic Pressure Gel (APG) technology, the conductor and epoxy resin insulator are molded in a single casting process. This integrated design eliminates internal interfaces and voids, forming a dense, flawless monolithic structure. Its advantages include:

Superior Insulation: Exhibits extremely high dielectric strength and outstanding arc resistance.

Mechanical Strength: Robust construction withstands electrodynamic and mechanical stresses, preventing deformation.

Environmental Stability: Highly hydrophobic, resistant to humid heat, UV radiation, and aging, suitable for harsh environments.

3. High-Conductivity Silver-Plated Copper Conductive Rod

The core conductor utilizes premium T2 copper with a silver-plated surface. This material combination delivers:

Low Resistivity: T2 copper's inherent high conductivity ensures low-energy transmission.

Enhanced Surface Properties: The silver plating not only further boosts conductivity but significantly improves surface oxidation resistance and corrosion resistance, guaranteeing stable contact and low contact resistance during long-term operation.

4. Fully Shielded, Fully Sealed Connection Interface

This sleeve is designed for use with fully compatible detachable cable connectors (elbow plugs). When connected, it achieves:

Electrical Full Shielding: The complete shielding structure ensures uniform electric field distribution, effectively preventing corona discharge and partial discharge to guarantee operational safety.

Environmental Full Sealing: Superior interface sealing performance effectively prevents moisture, dust, and humidity ingress, safeguarding the purity of the SF6 gas chamber and ensuring long-term operational reliability of the ring main unit.

Ⅲ. Electrical Performance Parameters of 160 Epoxy Resin Bushing

NKS-EB-12/250- | Description | 160 Epoxy Bushing |

| Technical Parameters | System Voltage | 12kV |

Rated current | 250A |

Frequency withstand voltage(AC) | 42kV/1min |

Partial Discharge | 15kV<5pC |

Impulse voltage | 95kV ±10times |

Capacitance value

| 18±3PF

|

The product has passed the inspection and certification of the China Electric Power Research Institute (CEPRI) Power Industry Electrical Equipment Quality Inspection and Testing Center

Type test reference standard: IEC 60502-4:2010 GB/T 12706.4-2008